In the field of metalworking, precision and expertise are paramount. Nhat Nam Mechanical is a leader in the industry, providing top-notch sheet metal bending services. This article explores the intricacies of sheet metal bending, showcasing why Nhat Nam Mechanical is the preferred choice for businesses seeking excellence in metal fabrication.

Sheet metal bending is an important process in manufacturing, helping to turn flat sheets into precise, functional parts. From automotive parts to electronic housings, bent metal items are now widely used and ubiquitous. This article delves into the methods, advantages and applications of sheet metal bending, especially highlighting the superior services of Nhat Nam Mechanical.

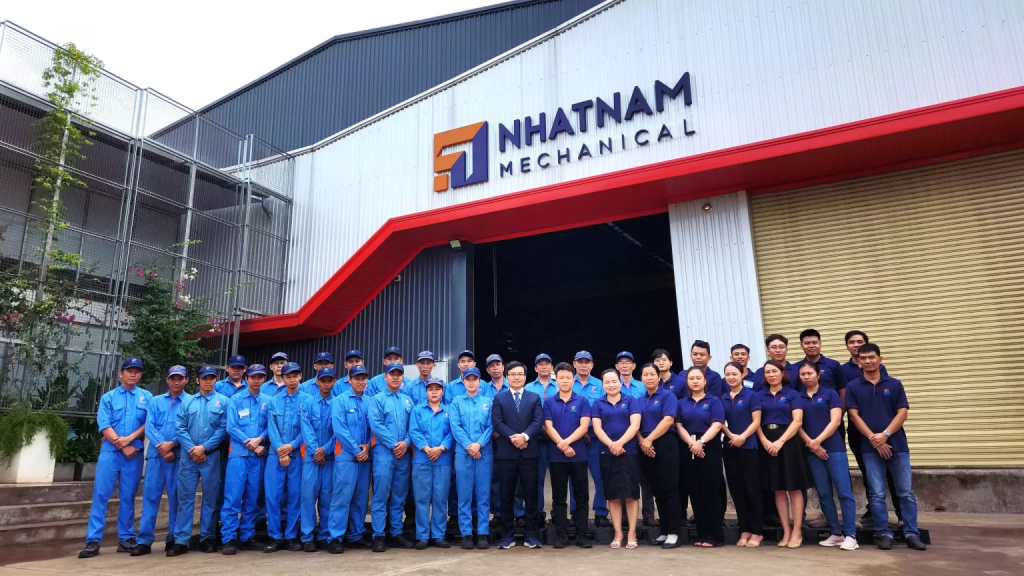

About Nhat Nam Mechanical

Established with the commitment “Peace of mind – Absolute trust“, Nhat Nam Mechanical has developed into a leading metal processing company. Our history is marked by innovation and customer satisfaction. We pride ourselves on our core values of quality, reliability and sustainability.

At Nhat Nam Mechanical, our mission is to provide superior metal fabrication solutions. With a team of experienced professionals and advanced technology, we handle projects of all sizes and complexities from small to large. Our expertise includes a variety of metalworking processes, with sheet metal bending being the foundation of our services.

Understanding Sheet Metal Bending

Sheet metal bending is the process of deforming a metal sheet to a desired angle or shape without altering its volume. This technique is essential in creating components with specific geometries and is used extensively across industries.

Materials Used in Sheet Metal Bending Various metals can be bent, including:

- Steel

- Aluminum

- Copper

- Brass

- Titanium

Each material will have its own characteristics that affect its ability to bend. For example, aluminum is light and malleable, making it suitable for complex designs, while steel is harder to bend but provides strength and durability for heavy-duty applications.

Common Applications Sheet metal bending finds applications in:

- Automotive panels

- Aircraft parts

- HVAC systems

- Structural components

- Consumer electronics

The Sheet Metal Bending Process

Sheet metal bending involves several steps to achieve precise results. Understanding these steps helps in appreciating the complexity and skill involved.

Step-by-Step Explanation

- Design and Planning: Engineers create detailed designs using CAD software, specifying the material, thickness, and bend angles.

- Cutting: Sheets are cut to size using shearing, laser cutting, or water jet cutting.

- Positioning: The cut sheet is positioned on a die corresponding to the desired bend shape.

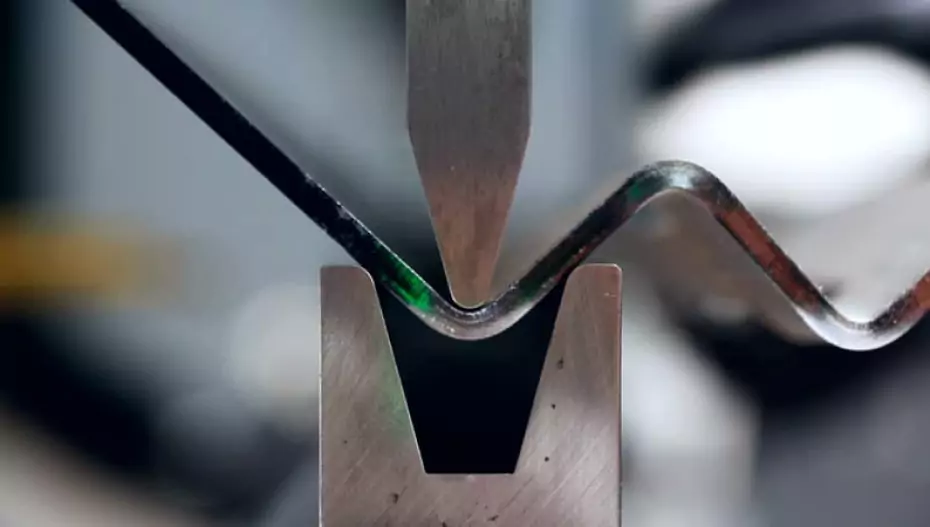

- Bending: A punch presses the sheet into the die, creating the bend. This can be done using various techniques.

Types of Bending Techniques

- V-Bending: Common and versatile, involving a V-shaped die and punch.

- Air Bending: The punch does not touch the bottom of the die, allowing for varying angles.

- Coining: High precision method where the punch presses the sheet into the die with greater force.

Machinery and Tools Involved Nhat Nam Mechanical uses advanced machinery, including CNC press brakes and hydraulic presses, ensuring precision and efficiency in every bend.

Why Choose Nhat Nam Mechanical for Sheet Metal Bending

Choosing the right partner for sheet metal bending is crucial. Nhat Nam Mechanical stands out due to several factors:

- Advanced Technology and Equipment: Our facility is equipped with the latest technology, enabling us to handle complex projects with high precision. CNC machines and automated systems ensure consistency and quality.

- Skilled Workforce: Our team comprises highly trained professionals with extensive experience in metalworking. Their expertise ensures that each project meets the highest standards.

- Quality Assurance Processes: We implement rigorous quality control measures at every stage of the process. From material selection to final inspection, our commitment to quality is unwavering.

- Customization Options: We offer customized solutions tailored to meet specific requirements. Whether it’s a one-off prototype or large-scale production, we provide flexibility and precision.

Benefits of Professional Sheet Metal Bending Services

Professional sheet metal bending services offer numerous advantages:

- Precision and Accuracy: Advanced machinery and skilled technicians ensure that bends are precise, meeting exact specifications.

- Cost-Effectiveness: Professional services reduce material waste and improve efficiency, lowering overall costs.

- Durability and Strength: Proper bending techniques enhance the structural integrity of metal components, ensuring longevity.

- Versatility in Design: Professional bending services allow for complex designs and shapes, expanding the possibilities for innovation.

Industries Served: Nhat Nam Mechanical serves a diverse range of industries, each with unique requirements:

- Automotive: We provide components for various automotive applications, including body panels, chassis parts, and exhaust systems.

- Aerospace: Precision and reliability are crucial in aerospace. We deliver high-quality components that meet stringent industry standards.

- Construction: Our metal bending services cater to construction needs, providing structural components and custom metalwork.

- Electronics: From enclosures to intricate parts, we supply the electronics industry with precision-bent metal components.

- Consumer Goods: We produce a variety of consumer products, ensuring high quality and durability.

Case Studies and Testimonials

Our success stories and customer testimonials speak volumes about our commitment to excellence:

- Case Study: Automotive Industry A leading automotive manufacturer approached us for custom body panels. Our precision bending ensured perfect fit and finish, enhancing the vehicle’s aesthetics and performance.

- Testimonial: Aerospace Client “Nhat Nam Mechanical consistently delivers high-quality components. Their precision and attention to detail are unmatched.”

Sustainability and Environmental Responsibility

Nhat Nam Mechanical is committed to sustainable practices:

- Eco-Friendly Practices We adopt eco-friendly practices in our operations, minimizing waste and reducing energy consumption.

- Recycling and Waste Management We implement comprehensive recycling and waste management programs, ensuring minimal environmental impact.

How to Request a Quote Visit our website and fill out the request form, or contact our sales team directly. We provide prompt and detailed quotes for all projects.

Ready to experience the best in sheet metal bending? Contact Nhat Nam Mechanical today:

Contact Details

- Phone: +84 938 771 508

- Email: tranquy@cokhinhatnam.vn

- Address: 245 Phan Dang Luu, Tan Cang Hamlet, Phuoc Tan Ward, Bien Hoa, Dong Nai province, Vietnam

Consultation Process Our experts will work with you to understand your requirements, offering tailored solutions to meet your needs.

By choosing Nhat Nam Mechanical for your sheet metal bending needs, you’re opting for precision, quality, and reliability. Contact us today to discuss your project and discover how we can bring your ideas to life.

To better understand Sheet Metal Forming Services, you can read more article: Sheet Metal Stamping