In the fast-evolving world of electronics, Sheet metal fabrication plays a pivotal role in creating durable and functional components. From enclosures and frames to intricate connectors, metal fabrication provides the foundation for many electronic devices. Whether you’re designing consumer electronics, industrial machinery, or cutting-edge medical equipment, understanding the importance of metal fabrication in electronics can give you a competitive edge.

What is Metal Fabrication for Electronics?

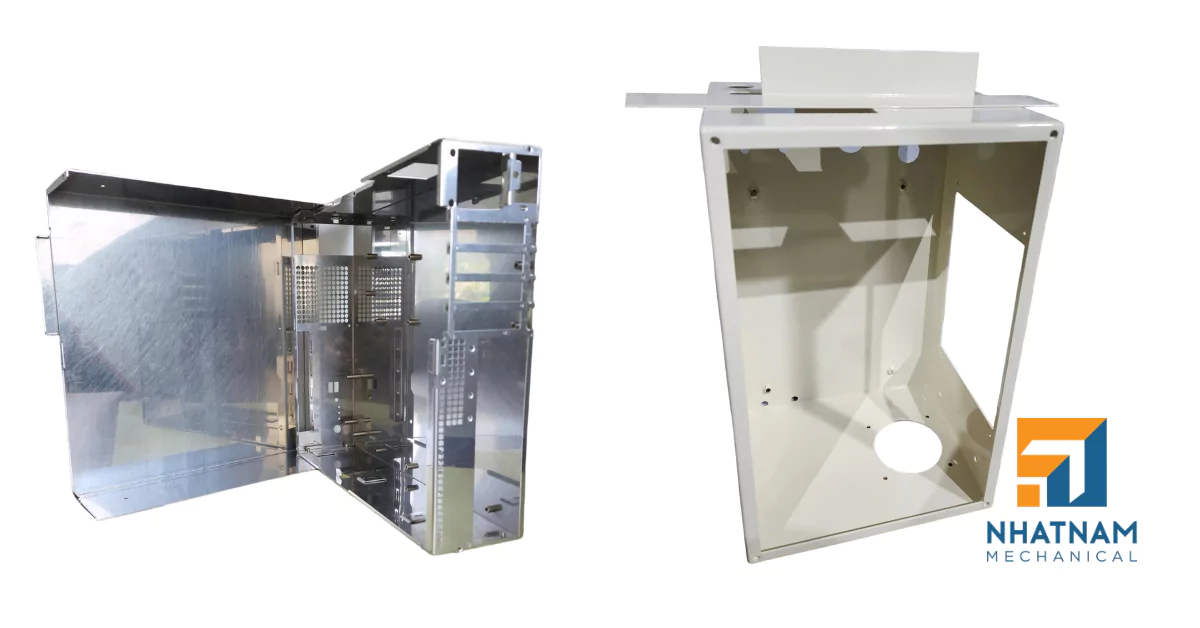

Metal fabrication for electronics involves a series of processes, including laser cutting, bending, forming, and assembling metal parts to create components that house and support electronic systems. This meticulous process ensures that the electronic devices are protected, efficiently cooled, and securely mounted.

Key Metal Fabrication Techniques for Electronics

Laser Cutting: This high-precision method uses a laser to cut metal sheets into intricate shapes, ideal for creating detailed and precise components.

CNC Machining: Utilizing computer-controlled machines, CNC machining provides unparalleled accuracy and consistency in cutting, drilling, and shaping metal parts.

Sheet Metal Forming: Techniques like bending, stamping, and deep drawing transform flat metal sheets into complex shapes, essential for creating custom enclosures and chassis.

Welding and Soldering: These processes are crucial for joining metal parts. While welding provides structural integrity, soldering is used for delicate electronic connections.

Surface Finishing: To enhance the appearance, durability, and conductivity of metal parts, surface treatments like powder coating, anodizing, and electroplating are applied.

Materials Used in Electronic Metal Fabrication

Choosing the right material is crucial for the performance and longevity of electronic components. Common materials include:

- Aluminum: Lightweight and corrosion-resistant, ideal for heat dissipation.

- Stainless Steel: Known for its strength and resistance to corrosion, suitable for harsh environments.

- Copper: Excellent electrical conductivity, often used in connectors and circuits.

- Alloys: Customized properties to meet specific requirements, such as increased strength or reduced weight.

Benefits of Metal Fabrication in Electronics

- Durability: Metal components provide a robust structure, protecting delicate electronic parts from damage.

- Precision: Advanced fabrication techniques ensure precise dimensions, crucial for fitting and functionality.

- Customization: Tailor-made solutions meet the specific needs of different electronic applications.

- Thermal Management: Metals like aluminum efficiently dissipate heat, preventing overheating of sensitive components.

Applications of Metal Fabrication in Electronics

Metal fabrication is essential across a wide range of electronic products, including:

- Consumer Electronics: Smartphones, laptops, and home appliances.

- Industrial Equipment: Control panels, sensors, and automation systems.

- Medical Devices: Diagnostic machines, surgical instruments, and wearable health monitors.

Why Choose Professional Metal Fabrication Services?

Partnering with a professional metal fabrication company ensures that your electronic components are manufactured to the highest standards. Expert fabricators offer:

- Advanced Technology: State-of-the-art equipment for precise and efficient fabrication.

- Experienced Craftsmanship: Skilled professionals with expertise in handling various materials and techniques.

- Quality Assurance: Rigorous testing and inspection processes to ensure the reliability of every component.

Regarding how Nhat Nam Mechanical’s sheet metal fabrication services can help your project involving galvanized steel, here are some ways:

- Custom Fabrication: We can work with galvanized steel sheets to fabricate custom components or structures based on your project requirements. We can cut, bend, and shape the galvanized steel to create the desired shapes and sizes.

- Welding and Joining: If your project requires the joining of galvanized steel pieces, Nhat Nam Mechanical can provide welding services to securely bond the components together. We have expertise in various welding techniques suitable for galvanized steel.

- Finishing and Surface Treatment: We can provide surface treatments for galvanized steel products, such as painting or powder coating. This can enhance the appearance, provide additional protection, or meet specific project requirements.

- Prototyping and Production: Whether you need a one-off prototype or a large production run, Nhat Nam Mechanical can assist with both. We can fabricate galvanized steel components or assemblies in the desired quantities to support your project.

It’s important to discuss your specific project requirements with Nhat Nam Mechanical to determine the extent of our capabilities and how we can best assist you with your galvanized steel fabrication needs.

NHAT NAM MECHANICAL CO., LTD contact information: House No. 36, Garland – Phuoc Dien, 72 Duong Dinh Hoi, Phuoc Long B Ward, District 9, Ho Chi Minh City, Vietnam

Contact Japan

Email: tranquy@cokhinhatnam.vn

Tel: +84 938 771 508

Contact English

Email: marketing@cokhinhatnam.vn

Tel: +84 964 092 079

Contact Vietnam

Email: vinhnt@cokhinhatnam.vn

Tel: +84 964 084 479