Fiber laser cutting is rapidly emerging as the preferred technology in sheet metal processing, thanks to its unparalleled precision, speed, and versatility. This article explores why fiber laser cutting is set to dominate the future of this industry and how it outperforms traditional cutting methods.

What is fiber laser cutting?

Fiber laser cutting is a metal cutting process that uses a fiber laser as the energy source. Fiber lasers are a type of solid-state laser where the active medium is an optical fiber doped with rare-earth elements like ytterbium. These lasers produce a focused beam of light with high energy density, which can be directed at materials to cut through them with precision and speed.

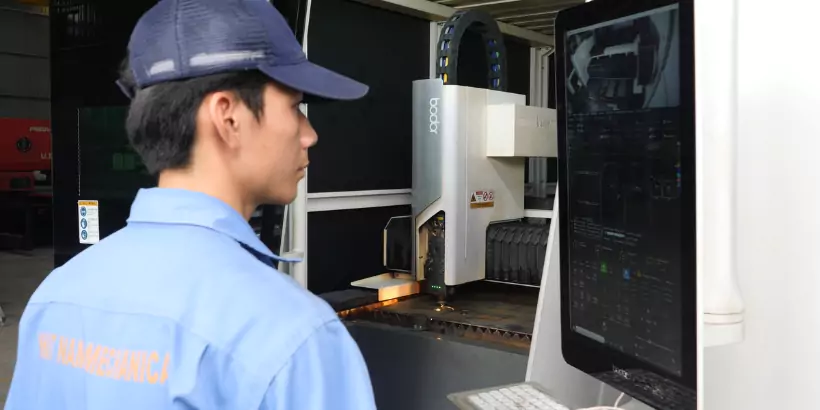

At Nhat Nam Mechanical, we offer precise fiber laser services including tube laser cutting and sheet metal laser cutting technology. This shift is driven by several key factors that set fiber laser cutting apart from traditional methods. Below are the reasons why fiber laser cutting is poised to dominate the future of sheet metal processing:

1. Superior Precision and Quality

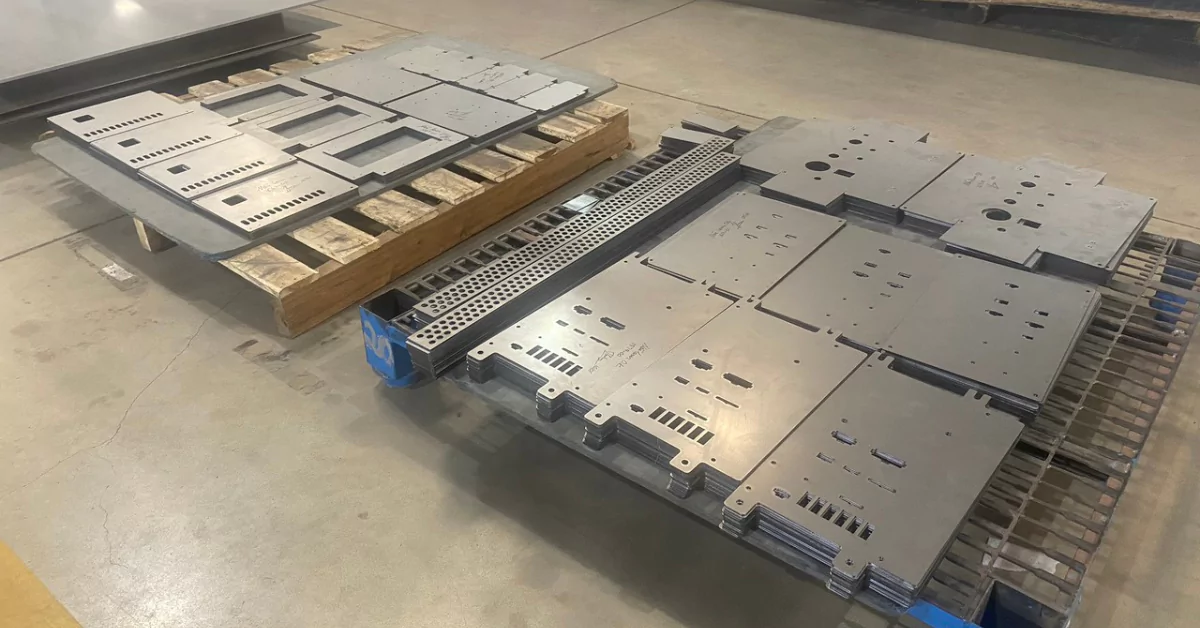

Fiber laser cutting provides unmatched accuracy, making it ideal for industries where precision is critical. The laser’s ability to focus a high-energy beam on a small spot allows for extremely fine cuts, reducing material waste and ensuring cleaner edges. This precision is particularly important in industries like aerospace, automotive, and electronics, where even the smallest imperfections can impact product performance.

2. Faster Cutting Speeds

Compared to older technologies such as CO₂ lasers and plasma cutting, fiber laser cutting offers significantly higher cutting speeds, especially when working with thinner materials. This increased speed translates to higher production rates, allowing manufacturers to complete jobs faster and reduce lead times. This efficiency is crucial in today’s fast-paced manufacturing environment, where quick turnaround times are essential for meeting customer demands.

3. Energy Efficiency and Cost Saving

One of the key advantages of fiber laser technology is its energy efficiency. Fiber lasers consume less power than other laser technologies, which reduces operating costs. Additionally, they have fewer consumable parts, such as mirrors and gasses, leading to lower maintenance expenses. This combination of energy savings and reduced maintenance costs makes fiber laser cutting more economical in the long run, helping companies improve their bottom line.

4. Versatility in Material Handling

Fiber laser cutting is incredibly versatile and can process a wide range of materials, including steel, aluminum, copper, and brass. This versatility gives manufacturers the flexibility to work with various metals without needing to change tools or equipment. Moreover, fiber lasers can handle both thin and thick sheets with ease, making them suitable for a wide range of applications, from delicate electronic components to robust industrial machinery parts.

5. Automation and Integration with Industry 4.0

As manufacturing moves toward automation and smart factories, fiber laser cutting systems are easily integrated into automated production lines. Many fiber laser machines come equipped with advanced software and CNC controls, allowing for precise automation of the cutting process. This not only improves accuracy and reduces human error but also allows for continuous, 24/7 production with minimal supervision. Additionally, these systems can be connected to Industry 4.0 networks, providing real-time data for monitoring and optimizing the cutting process.

6. Reduced Environmental Impact

Fiber lasers produce minimal waste and consume less energy, making them more environmentally friendly than other cutting technologies. As industries place more emphasis on sustainability, fiber laser cutting aligns with green manufacturing practices by reducing carbon footprints and minimizing material waste

Regarding how Nhat Nam Mechanical’s sheet metal fabrication services can help your project involving galvanized steel, here are some ways:

- Custom Fabrication: We can work with galvanized steel sheets to fabricate custom components or structures based on your project requirements. We can cut, bend, and shape the galvanized steel to create the desired shapes and sizes.

- Welding and Joining: If your project requires the joining of galvanized steel pieces, Nhat Nam Mechanical can provide welding services to securely bond the components together. We have expertise in various welding techniques suitable for galvanized steel.

- Finishing and Surface Treatment: We can provide surface treatments for galvanized steel products, such as painting or powder coating. This can enhance the appearance, provide additional protection, or meet specific project requirements.

- Prototyping and Production: Whether you need a one-off prototype or a large production run, Nhat Nam Mechanical can assist with both. We can fabricate galvanized steel components or assemblies in the desired quantities to support your project.

It’s important to discuss your specific project requirements with Nhat Nam Mechanical to determine the extent of our capabilities and how we can best assist you with your galvanized steel fabrication needs.

NHAT NAM MECHANICAL CO., LTD contact information: House No. 36, Garland – Phuoc Dien, 72 Duong Dinh Hoi, Phuoc Long B Ward, District 9, Ho Chi Minh City, Vietnam

Contact Japan

Email: tranquy@cokhinhatnam.vn

Tel: +84 938 771 508

Contact English

Email: marketing@cokhinhatnam.vn

Tel: +84 964 092 079

Contact Vietnam

Email: vinhnt@cokhinhatnam.vn

Tel: +84 964 084 479