1. What is Sheet Metal Punching?

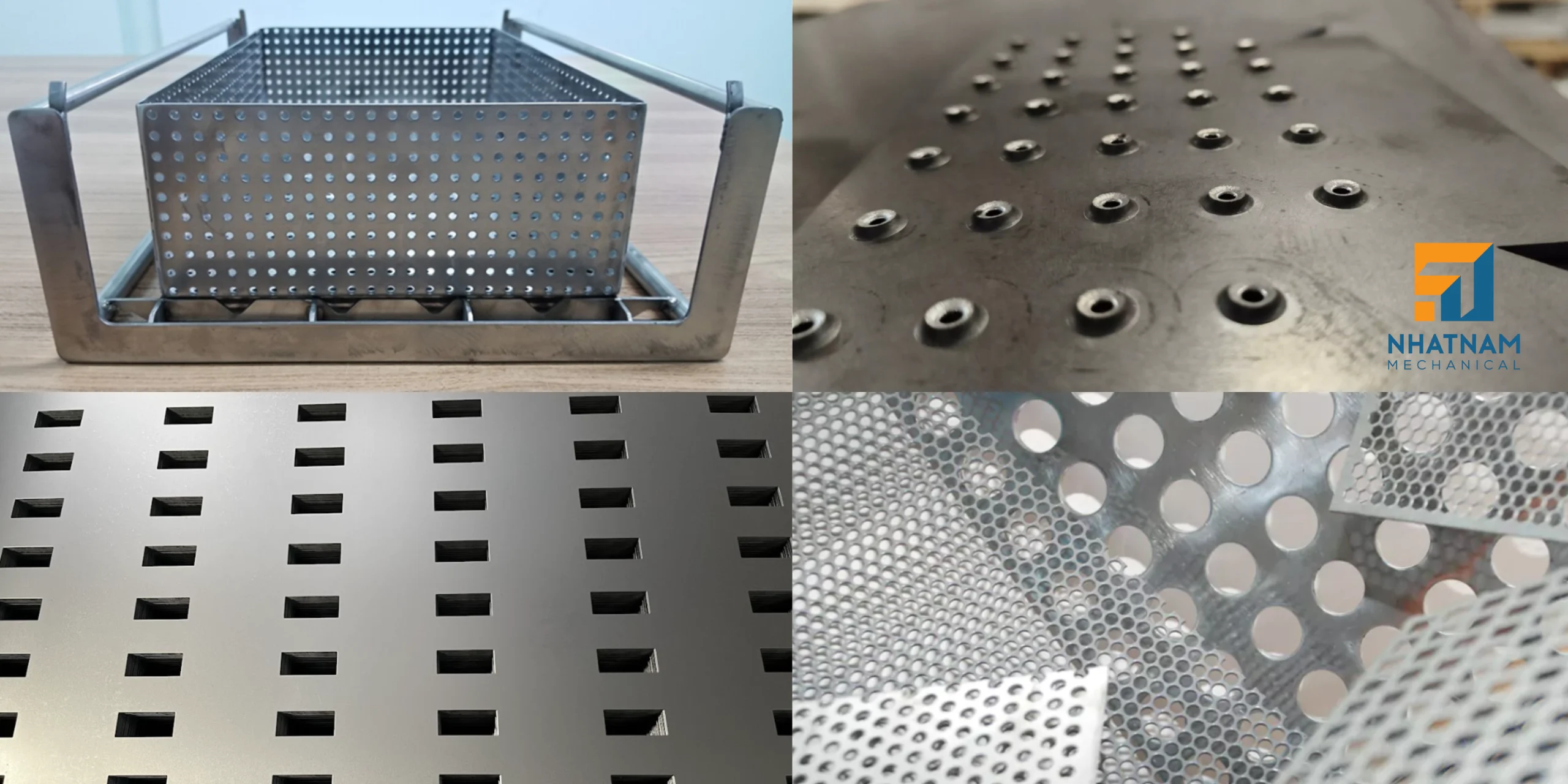

Sheet metal punching is the process of creating holes on the surface of the material using mechanical methods or modern technology. This process can create simple holes (round, square, rectangular…) or complex patterns for many different purposes such as:

- Increase aesthetics: Applied in architecture, interior decoration.

- Reduce weight: Applied in the automotive and aviation industries to reduce load while maintaining durability.

- Create ventilation holes: Used in radiator systems, air filters.

- Support assembly: Provide locations for screwing, joining mechanical parts.

Common methods for punching include:

- Mechanical punching: Using a stamping machine with a fixed mold to create holes in the metal.

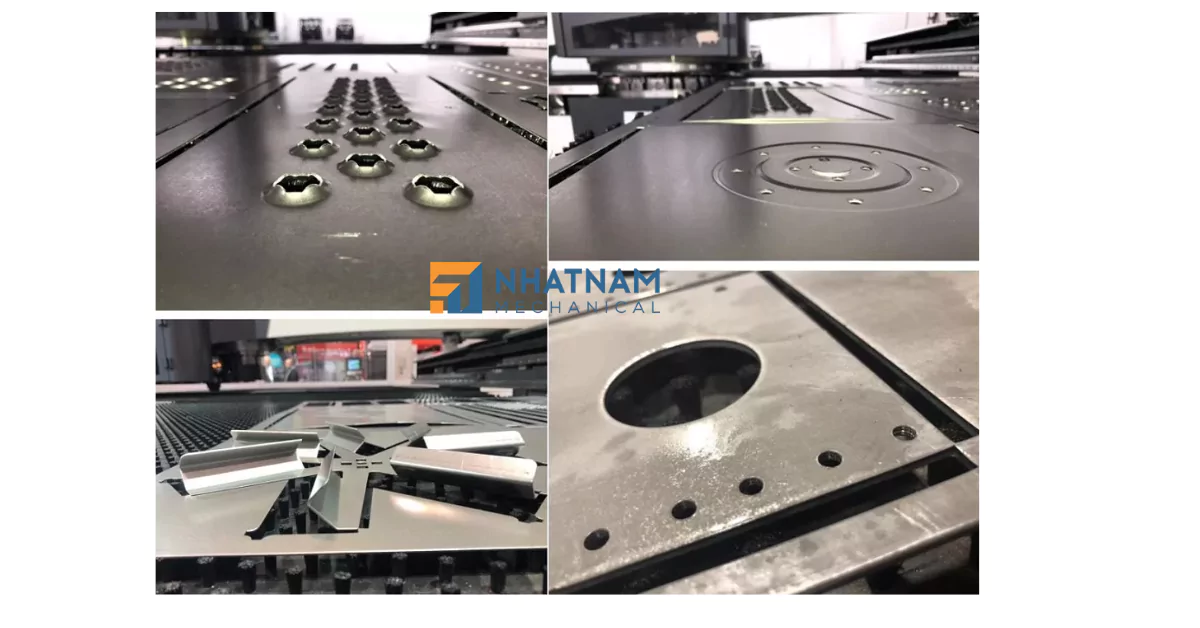

- CNC punching: Controlled by computer, helping to process accurately at high speed.

- Laser or plasma cutting: Allows for creating custom-shaped holes with greater precision than traditional methods.

2. History of Punching Technology

Early stages (before the 19th century)

- Punching holes on sheet metal was done manually with hammers and iron chisels.

- Mainly used in the manufacture of weapons, armor, and protective screens.

- Manual processes were labor-intensive and did not guarantee uniformity of the holes.

19th century – Industrial Revolution

- The appearance of mechanical machines helped increase productivity.

- Factories began using punching machines to punch holes on a large scale.

- Metal mesh, filters, and punched components were mass-produced, serving new industries.

20th century – Mechanization and automatic control

- The development of hydraulic and pneumatic punches helped increase processing speed. CNC technology was born in the 1950s and 1960s, allowing for more precise machining.

- The automotive, aerospace, and electronics industries began to apply large-scale punching.

- Punching began to be applied in architectural and interior design thanks to decorative patterns.

21st Century – Advanced Technology and Automation

- The emergence of fiber laser cutting technology allows for fast, precise machining without causing material deformation.

- AI systems and simulation software help optimize hole design for maximum performance.

- The trend of sustainable manufacturing helps reduce material waste and improve energy efficiency.

3. Future Trends of Punching Technology

- Punching technology in sheet metal is entering a new era with the support of automation, AI, and advanced manufacturing methods. These improvements not only help improve performance but also reduce costs and environmental impact. Here are the key trends that will shape the future of the industry.

- Integration of AI and automation: Machines are learning to optimize cutting paths and reduce material waste.

- Digital design: Advanced software helps create mechanically and aesthetically optimized punching patterns.

- Smart and sustainable manufacturing: Factories are adopting Industry 4.0 technology to improve production efficiency and reduce environmental impact.

- Sustainable Manufacturing and Waste Reduction Trends

As businesses move towards “green” manufacturing, the metal punching industry is also shifting towards sustainability criteria: reusing and reducing material waste, saving energy, and using environmentally friendly materials.

Conclusion

Punching in sheet metal has evolved from manual methods to modern technologies such as CNC, laser, and AI. In the future, the industry will continue to innovate to meet the needs of precise, fast and environmentally friendly production.

Nhat Nam Mechanical is proud to be the leading unit in the field of sheet metal processing in Vietnam, providing high precision punching services with advanced technology. We own a modern CNC punching machine system, capable of processing quickly, accurately and meeting all complex design requirements. Promise to bring you high quality products at affordable prices.

NHAT NAM MECHANICAL CO., LTD contact information: House No. 36, Garland – Phuoc Dien, 72 Duong Dinh Hoi, Phuoc Long B Ward, District 9, Ho Chi Minh City, Vietnam

Contact Japan

Email: tranquy@cokhinhatnam.vn

Tel: +84 938 771 508

Contact English

Email: marketing@cokhinhatnam.vn

Tel: +84 964 092 079

Contact Viet Nam

Email: vinhnt@cokhinhatnam.vn

Tel: +84 964 084 479