Sheet Metal Materials: Stainless Steel

Steel Metal Materials : Stainless Steel

1. The story of stainless steel

The structure of stainless steel is characterized by the presence of a protective chromium-rich passive film on the surface, as well as the alloy composition and microstructure within the material.

Brearley’s discovery was initially called “rustless steel” and was primarily used in industrial applications such as cutlery, chemical plants, and surgical instruments. However, it was not until the 1920s and 1930s that stainless steel began to gain widespread commercial use.

In 1929, the American metallurgist Elwood Haynes created a stainless-steel alloy that contained a higher percentage of chromium and also included nickel. This alloy, known as “18-8” stainless steel, became the basis for the modern stainless-steel industry.

During World War II, stainless steel saw significant advancements and grew in importance. It was used in military applications such as aircraft construction and weaponry, as well as in various civilian industries. After the war, stainless steel became more affordable and accessible, leading to its increased use in everyday products and applications.

Since its inception, stainless steel has continued to evolve and improve. New grades and alloys have been developed to meet specific industry requirements, such as increased strength, resistance to extreme temperatures, or enhanced corrosion resistance. Today, stainless steel is one of the most versatile and widely used materials in numerous industries worldwide.

2. The Structure of stainless steel

The structure of stainless steel is characterized by the presence of a protective chromium-rich passive film on the surface, as well as the alloy composition and microstructure within the material.

The key structural features of stainless steel are:

Passive Film:

- The addition of chromium (minimum 10.5%) to the steel alloy allows for the formation of a thin, invisible, and highly stable chromium-oxide passive film on the surface.

- This passive film acts as a barrier, protecting the underlying metal from corrosion and oxidation.

- The passive film is self-healing, meaning that if it is damaged, it can reform quickly to maintain the corrosion resistance.

Microstructure:

- The microstructure of stainless steel can be either austenitic, ferritic, martensitic, or duplex (a combination of austenitic and ferritic).

- The microstructure is determined by the specific alloying elements and heat treatment processes used during manufacturing.

- Austenitic stainless steels (e.g., 304, 316) have a face-centered cubic (FCC) crystal structure and are known for their excellent ductility, formability, and corrosion resistance.

- Ferritic stainless steels (e.g., 430) have a body-centered cubic (BCC) crystal structure and are generally less expensive but have lower corrosion resistance compared to austenitic grades.

- Martensitic stainless steels (e.g., 410) have a body-centered tetragonal (BCT) crystal structure and are known for their high hardness and strength, but lower corrosion resistance.

- Duplex stainless steels (e.g., 2205) have a microstructure that is a combination of austenite and ferrite, providing a balance of strength, corrosion resistance, and weldability.

Alloying Elements:

- In addition to the minimum 10.5% chromium, stainless steel may contain other alloying elements such as nickel, molybdenum, manganese, and silicon.

- These alloying elements contribute to the specific properties of the stainless steel, such as corrosion resistance, strength, and formability.

- The precise composition of the alloy determines the grade and performance characteristics of the stainless steel.

The unique structure of stainless steel, with its passive film and controlled microstructure, gives it superior corrosion resistance, mechanical properties, and overall durability compared to regular carbon steel, making it a versatile and widely used material in various industries.

3. Grades of stainless steel

Here are some of the main grades of stainless steel and their key characteristics:

304 Stainless Steel:

- Also known as 18/8 stainless steel

- Contains 18% chromium and 8% nickel

- Highly resistant to corrosion and widely used in food processing, kitchen equipment, and medical applications

316 Stainless Steel:

- Contains 16-18% chromium and 10-14% nickel, with the addition of molybdenum

- Provides enhanced corrosion resistance, especially to chlorides and acids

- Often used in marine environments, chemical processing, and medical devices

410 Stainless Steel:

- Contains 11.5-13.5% chromium

- Has higher strength and hardness compared to 304 and 316 grades

- Used in cutlery, tools, and machinery components

430 Stainless Steel:

- Contains 16-18% chromium

- Offers good corrosion resistance and is less expensive than 304 and 316 grades

- Commonly used in kitchen appliances, automotive trim, and architectural applications

202 Stainless Steel:

- Contains 17-19% chromium and 4-6% nickel

- Provides good corrosion resistance and is more cost-effective than 304 stainless steel

- Utilized in food service equipment, architectural applications, and automotive parts

These are just a few of the most common stainless steel grades, and each grade has its own unique properties and applications based on its chemical composition and manufacturing process. The choice of stainless steel grade often depends on the specific requirements of the application, such as corrosion resistance, strength, and cost considerations.

4. The key features and characteristics of stainless steel

These are just a few of the most common stainless steel grades, and each grade has its own unique properties and

Corrosion Resistance:

- Stainless steel is highly resistant to corrosion, rust, and staining due to the formation of a passive chromium-oxide film on the surface.

- This makes stainless steel suitable for use in environments where it is exposed to moisture, chemicals, or harsh weather conditions.

Durability and Strength:

- Stainless steel has higher tensile strength and hardness compared to regular carbon steel.

- It can withstand heavy loads, impact, and abrasion, making it suitable for a wide range of applications.

Appearance and Finish:

- Stainless steel has a shiny, lustrous appearance that is often desired for aesthetic purposes.

- It can be polished to a high-gloss finish or brushed to create a matte appearance.

Hygienic and Easy to Clean:

- The smooth, non-porous surface of stainless steel makes it easy to clean and maintain, making it suitable for use in food processing, healthcare, and other hygienic applications.

Heat Resistance:

- Stainless steel can withstand high temperatures without losing its strength or structural integrity.

- This property makes it suitable for use in various high-temperature applications, such as cooking equipment and industrial machinery.

5. Applications of stainless steel

Stainless steel has a wide range of applications across various industries due to its desirable properties. Sheet metal fabrication services specifically focus on transforming stainless steel sheets into desired shapes and products through cutting, bending, welding, and assembly processes. These services provide customization options to cater to specific project requirements and yield finished products that meet industry standards.

Stainless steel's exceptional properties and sheet metal fabrication services combine to offer a wide range of applications across industries, contributing to its popularity in the manufacturing and construction sectors.

Here are some of the key uses of stainless steel:

Food and Beverage Industry:

- Stainless steel is extensively used in food processing equipment, kitchen appliances, and food preparation surfaces due to its corrosion resistance, easy cleaning, and sanitary properties.

- Examples include food processing machinery, storage tanks, countertops, sinks, and utensils.

Medical and Pharmaceutical Industry:

- Stainless steel is widely used in medical devices, surgical instruments, and pharmaceutical manufacturing equipment due to its biocompatibility and ability to withstand sterilization processes.

- Examples include surgical tools, implants, hospital furniture, and laboratory equipment.

Nhat Nam Engineering is proud to offer a range of stainless steel equipment tailored for pharmaceutical industries. Our machinery ensures compliance with stringent hygiene standards and facilitates precise processes in pharmaceutical manufacturing, from mixing to packaging. Trust in our products for efficiency, safety, and quality assurance in pharmaceutical production.

Architecture and Construction:

- Stainless steel is used in architectural applications for its aesthetic appeal, durability, and corrosion resistance.

- Examples include building facades, roofing, railings, and structural components.

Automotive and Transportation:

- Stainless steel is employed in various automotive parts and components, such as exhaust systems, trim, and fasteners, due to its strength and corrosion resistance.

- It is also used in the construction of rail cars, ships, and aircraft.

Chemical and Petrochemical Industry:

- Stainless steel is highly resistant to a wide range of chemicals and is used in the construction of storage tanks, piping, and other equipment in chemical and petrochemical plants.

Household Appliances and Cookware:

- Stainless steel is a popular material for kitchen appliances, cookware, and utensils due to its durability, easy cleaning, and aesthetic appeal.

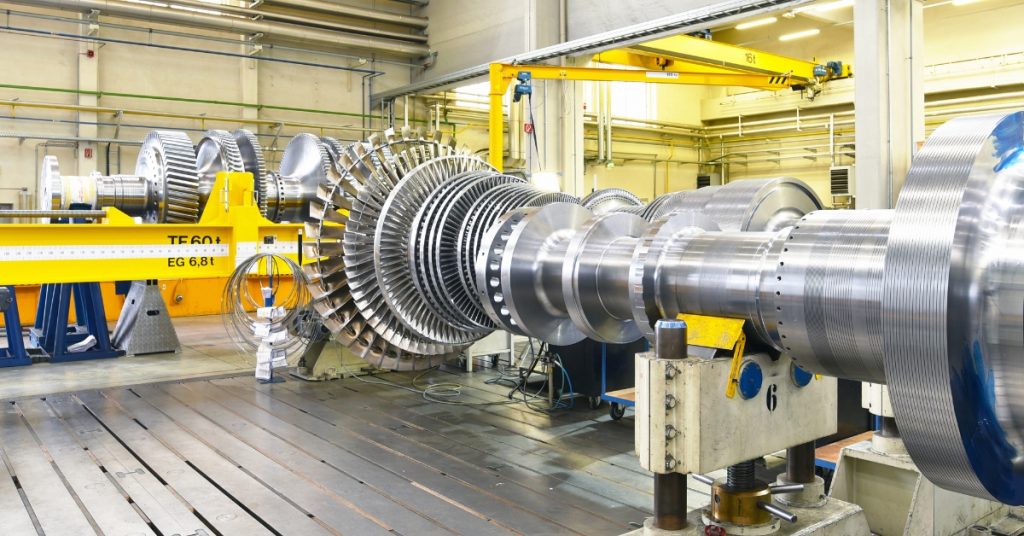

Power Generation:

- Stainless steel is used in power generation equipment, such as turbines, generators, and heat exchangers, due to its strength, corrosion resistance, and high-temperature performance.

The versatility of stainless steel, combined with its corrosion resistance, strength, and hygienic properties, makes it a widely used material across a diverse range of industries and applications.

Nhat Nam Mechanical co., Ltd. offer complete supply chain management solutions, including sourcing materials and components using our extensive network of trusted suppliers. And with wide range of sheet metal fabrication, finishing options, kitting and packaging services, we deliver finished goods ready to ship to your warehouse or drop-ship directly to your customer.