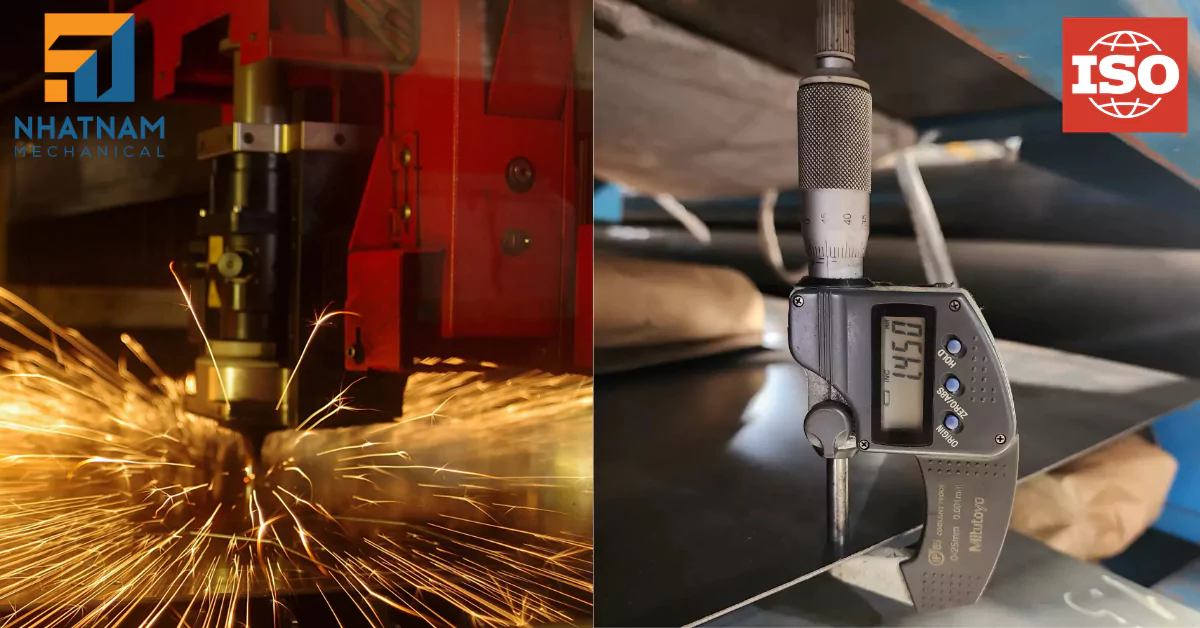

Laser cutting is a widely adopted method in metal fabrication, prized for its precision and efficiency. However, achieving consistent and accurate cuts requires adherence to established tolerance standards. ISO standards, particularly ISO 9013, provide a framework for ensuring quality in laser cutting processes. Below, we delve into the key aspects of laser cutting tolerance and the role ISO standards play in guiding manufacturers.

What is Laser Cutting Tolerance?

Tolerance refers to the permissible variation in dimensions or geometry of a laser-cut component. It dictates the maximum allowable deviation between the design specification and the final product. Precise tolerances are essential for:

- Ensuring parts fit and function as intended.

- Reducing material waste.

- Meeting client and industry-specific requirements.

ISO 9013: A Standard for Thermal Cutting

ISO 9013 is the primary standard governing quality in thermal cutting processes, including laser cutting. This standard classifies the quality of cuts based on geometric tolerances and surface roughness. Key parameters outlined in ISO 9013 include:

- Dimensional Tolerances: Specifies the acceptable range of deviation in part dimensions.

- Categories are defined by tolerance classes (e.g., fine, medium, and coarse tolerances).

- Edge Quality (Surface Roughness): Assesses the smoothness of the cut edge, measured in micrometers (µm).

- ISO 9013 defines roughness grades, ensuring edges meet application-specific requirements.

- Angular Tolerance: Evaluates the perpendicularity of the cut face relative to the material’s surface.

- Critical for components requiring precise assembly.

- Heat-Affected Zone (HAZ): Monitors the area affected by laser heat to prevent material property degradation.

Sheet Metal Materials

| Gauge | Steel | Galvanized | Stainless | Aluminum | ||||

|---|---|---|---|---|---|---|---|---|

| in | mm | in | mm | in | mm | in | mm | |

| 3 | 0.2391 | 6.07 | ||||||

| 4 | 0.2242 | 5.69 | ||||||

| 5 | 0.2092 | 5.31 | ||||||

| 6 | 0.1943 | 4.94 | 0.1620 | 4.11 | ||||

| 7 | 0.1793 | 4.55 | 0.1875 | 4.76 | 0.1443 | 3.67 | ||

| 8 | 0.1644 | 4.18 | 0.1681 | 4.27 | 0.1719 | 4.37 | 0.1285 | 3.26 |

| 9 | 0.1495 | 3.80 | 0.1532 | 3.89 | 0.1563 | 3.97 | 0.1144 | 2.91 |

| 10 | 0.1345 | 3.42 | 0.1382 | 3.51 | 0.1406 | 3.57 | 0.1019 | 2.59 |

| 11 | 0.1196 | 3.04 | 0.1233 | 3.13 | 0.1250 | 3.18 | 0.0907 | 2.30 |

| 12 | 0.1046 | 2.66 | 0.1084 | 2.75 | 0.1094 | 2.78 | 0.0808 | 2.05 |

| 13 | 0.0897 | 2.28 | 0.0934 | 2.37 | 0.0940 | 2.39 | 0.0720 | 1.83 |

| 14 | 0.0747 | 1.90 | 0.0785 | 1.99 | 0.0781 | 1.98 | 0.0641 | 1.63 |

| 15 | 0.0673 | 1.71 | 0.0710 | 1.80 | 0.0700 | 1.78 | 0.0570 | 1.45 |

| 16 | 0.0598 | 1.52 | 0.0635 | 1.61 | 0.0625 | 1.59 | 0.0508 | 1.29 |

| 17 | 0.0538 | 1.37 | 0.0575 | 1.46 | 0.0560 | 1.42 | 0.0450 | 1.14 |

| 18 | 0.0478 | 1.21 | 0.0516 | 1.31 | 0.0500 | 1.27 | 0.0403 | 1.02 |

| 19 | 0.0418 | 1.06 | 0.0456 | 1.16 | 0.0440 | 1.12 | 0.0360 | 0.91 |

| 20 | 0.0359 | 0.91 | 0.0396 | 1.01 | 0.0375 | 0.95 | 0.0320 | 0.81 |

| 21 | 0.0329 | 0.84 | 0.0366 | 0.93 | 0.0340 | 0.86 | 0.0280 | 0.71 |

| 22 | 0.0299 | 0.76 | 0.0336 | 0.85 | 0.0310 | 0.79 | 0.0250 | 0.64 |

| 23 | 0.0269 | 0.68 | 0.0306 | 0.78 | 0.0280 | 0.71 | 0.0230 | 0.58 |

| 24 | 0.0239 | 0.61 | 0.0276 | 0.70 | 0.0250 | 0.64 | 0.0200 | 0.51 |

| 25 | 0.0209 | 0.53 | 0.0247 | 0.63 | 0.0220 | 0.56 | 0.0180 | 0.46 |

| 26 | 0.0179 | 0.45 | 0.0217 | 0.55 | 0.0190 | 0.48 | 0.0170 | 0.43 |

| 28 | 0.0149 | 0.38 | 0.0187 | 0.47 | 0.0160 | 0.41 | 0.0126 | 0.32 |

Sheet Metal Laser cutting Tolerances

| Laser Cutting | Material Thickness | |||||

|---|---|---|---|---|---|---|

| Linear Tolerances: X.XX | Hole Diameter Tolerances | 0.5 mm to 2.0 mm | 2.0 mm to 5.0 mm | 5.0 mm to 10.0 mm | 10.0 mm to 20.0 mm | |

| Standard Tolerances | +/- 0.45 mm | +/- 0.12mm | +/- 0.05 | +/- 0.10 | +/- 0.25 | +/- 0.50 |

| High Precision Tolerances | +/- 0.20mm | +/- 0.08mm | ||||

- Thin sheets typically yield finer tolerances.

- Material properties, such as hardness and reflectivity, also affect precision.

| MAXIMUM SHEET SIZE (mm) | ||||||

|---|---|---|---|---|---|---|

| Sheet Size | Q235/Q345 (mm) | SAPH440 (mm) | SPCC (mm) | SGCC (mm) | ALUMINUM (mm) | STAINLESS STEEL (mm) |

| 1,500 X 3,000 | 1,500 X 3,000 | 1,260 X 2,500 | 1,260 X 2,500 | 1,260 X 2,500 | 1,220 X 2,440 | 1,220 X 2,440 |

Operator Expertise:

- Skilled technicians optimize machine settings for specific materials and designs.

- Practical Applications of ISO 9013 in Laser Cutting

NHAT NAM MECHANICAL CO., LTD contact information: House No. 36, Garland – Phuoc Dien, 72 Duong Dinh Hoi, Phuoc Long B Ward, District 9, Ho Chi Minh City, Vietnam

Contact Japan

Email: tranquy@cokhinhatnam.vn

Tel: +84 938 771 508

Contact English

Email: marketing@cokhinhatnam.vn

Tel: +84 964 092 079

Contact Viet Nam

Email: vinhnt@cokhinhatnam.vn

Tel: +84 964 084 479