1. Introduction

Sheet metal fabrication is a crucial manufacturing process in various industries, including automotive, aerospace, electronics, construction, and furniture. Products made from sheet metal have different technical requirements depending on their use and operating environment. Below is a list of the main products and their most important technical requirements.

2. Sheet Metal Products and Technical Requirements

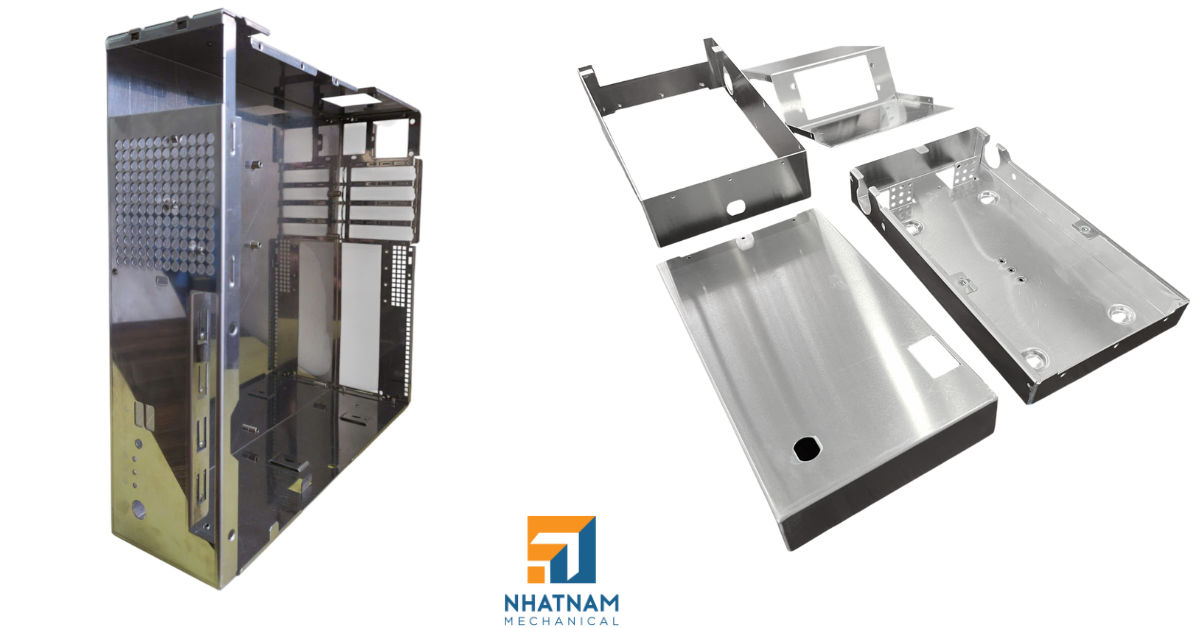

Industrial Machine Enclosures and Electrical Cabinets

- These products include CNC machine enclosures, industrial electrical cabinets, control cabinets, and electronic equipment protection boxes. They are used to protect electrical equipment and control systems from environmental impacts such as dust, moisture, and impact.

- Technical requirements include rust resistance, high durability, easy installation, and maintenance. They are usually made from stainless steel or powder-coated steel to enhance durability and oxidation resistance. Common material thicknesses range from 1mm to 3mm, depending on load-bearing requirements.

Automotive and Motorcycle Components

- Common products in this category include engine covers, protective frames, support systems, braces, battery covers, and vehicle frame structures.

- These products need to be strong, impact-resistant, and corrosion-resistant due to exposure to water, oil, and dirt. Commonly used metals include alloy steel, aluminum, and stainless steel, with precision machining processes such as laser cutting, embossing, and MIG/TIG welding to ensure stability and high durability.

Metal Structures in Construction

- This category includes products such as columns, beams, railings, scaffolding, steel structural frames, metal roofs, and steel doors.

- These products must ensure rigidity, withstand heavy loads, and resist corrosion in outdoor environments. Galvanized steel or stainless steel is often used to increase the lifespan and strength of these components. Additionally, processing methods such as arc welding, stamping, and anti-corrosion coating are applied to enhance product durability.

Aerospace Components

- Products in this category include aircraft skins, propellers, cabin frames, engine mounts, and lightweight structural parts.

- They need to be lightweight yet extremely strong to withstand high pressure, extreme temperatures, and ensure absolute safety. Aluminum alloys, titanium, and composite materials are popular choices to reduce weight while maintaining mechanical strength. The manufacturing process requires high precision, using advanced technologies such as 5-axis laser cutting, ultrasonic welding, and ultrasonic quality testing.

Electronic Device Housings and Frames

- This category includes computer cases, monitor frames, radiators, printer frames, speaker housings, and other electronic components.

- These products require high precision, good electromagnetic interference protection, shock resistance, and heat resistance. Anodized aluminum or stainless steel is often used to ensure aesthetics and durability. Processing requirements include precision stamping, CNC cutting, powder coating, and surface quality testing using laser measurement.

Furniture and Decoration

- Products such as metal tables and chairs, iron shelves, iron doors, stair handrails, metal partitions, and decorative lights must not only be durable but also meet aesthetic requirements. They are often powder-coated or chrome-plated to increase durability and resistance to oxidation.

- Technical requirements include precision in assembly, a smooth surface finish, and good load-bearing capacity. Some high-end furniture products may use stainless steel or gold-plated aluminum to enhance luxury.

Medical and Laboratory Components

- Products such as operating tables, equipment racks, instrument trays, medicine cabinets, and X-ray machine frames need to meet strict hygiene standards.

- They must be easy to clean, corrosion-resistant, and unaffected by disinfectants. Medical-grade stainless steel (usually 304 or 316 stainless steel) is a popular material to ensure durability and safety. Machining must ensure smooth, gap-free welds to prevent dust and bacteria buildup.

Heavy Industrial Products

- This category includes chemical tanks, storage tanks, piping systems, machine frames, and high-strength components used in the oil and gas, chemical, and machine manufacturing industries.

- These products must withstand high pressure, resist chemical corrosion, and ensure operational safety. Common materials include stainless steel or thick carbon steel, reinforced with high-quality welding and anti-corrosion coatings. Some chemical tanks have acid-resistant linings or epoxy coatings to increase durability in harsh environments.

3. Conclusion

Sheet metal fabrication plays an important role in many industries, from residential to heavy industry. Each product has its own technical requirements, requiring precise machining processes to ensure quality and durability. Understanding technical standards helps optimize production and meet usage needs.

4. Sheet Metal Processing Services at Nhat Nam Mechanical

Nhat Nam Mechanical Company is one of the leading units in the field of sheet metal processing in Vietnam. We specialize in providing services such as CNC laser cutting, metal stamping, bending, welding, and product surface finishing. With a modern machinery system and a team of experienced engineers, we are committed to delivering high-precision products with durable quality, fully meeting the strict technical standards of customers across various industries. Our services are widely applied in the production of industrial machine housings, automotive components, construction structures, medical equipment, and many other fields. Contact us for more detailed advice on your project.

NHAT NAM MECHANICAL CO., LTD contact information: House No. 36, Garland – Phuoc Dien, 72 Duong Dinh Hoi, Phuoc Long B Ward, District 9, Ho Chi Minh City, Vietnam

Contact Japan

Email: tranquy@cokhinhatnam.vn

Tel: +84 938 771 508

Contact English

Email: marketing@cokhinhatnam.vn

Tel: +84 964 092 079

Contact Vietnam

Email: vinhnt@cokhinhatnam.vn

Tel: +84 964 084 479