Sheet metal plays a vital role in many industries, from automotive and aerospace to construction and electronics. Technological advancements are driving dramatic improvements in sheet metal design and fabrication. Here are some of the emerging technology trends shaping the future of the industry.

1. Advanced Cutting Technology

Traditional cutting methods, such as knife cutting and plasma cutting, are being replaced by more advanced solutions like laser cutting and waterjet cutting. Laser cutting uses a high-powered laser beam, allowing complex metal parts to be cut with exceptional precision and smoothness. In addition, waterjet cutting, which uses a high-pressure stream of water mixed with abrasive particles to cut materials without melting or causing thermal effects on the material, is also becoming increasingly popular.

2. CNC Machining

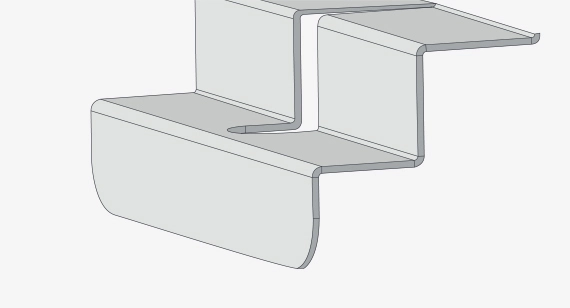

CNC machining has become the standard in sheet metal manufacturing due to its ability to precisely perform bending, punching, and welding processes. CNC machines reduce production time and increase product quality by ensuring consistency, high precision, and minimizing errors in production.

3. 3D Printing and Additive Manufacturing

3D printing and additive manufacturing are opening new doors in sheet metal design. 3D printing offers increased design flexibility by enabling complex shapes that are difficult to achieve with traditional methods. Additive manufacturing also saves material, reduces waste, and creates lighter, more efficient components.

4. Advanced Materials and Alloys

The development of new materials and alloys is changing the landscape of sheet metal design. Lightweight alloys such as aluminum and titanium, which offer high strength and low weight, are gaining popularity in the automotive and aerospace industries. The use of these materials not only reduces the weight of products but also increases operating efficiency and reduces fuel consumption.

5. Sustainable Manufacturing

With growing concerns about the environment, sustainable manufacturing processes are becoming a focus. Using renewable energy, optimizing processes to minimize waste, and recycling raw materials are important factors in modern sheet metal design and fabrication. This is not only an ethical responsibility but also a competitive advantage for businesses.

These improvements not only increase production efficiency but also open up new growth opportunities for the sheet metal industry. Technology is, and will continue to be, central in optimizing processes, benefiting both manufacturers and consumers.

At Nhat Nam, we are proud to be a leading sheet metal processing and design unit with advanced technology. With a team of experienced engineers and a fully automated process, we are committed to providing high quality products, quickly and flexibly meeting all customer requirements. Contact us to learn more about metal processing services at Nhat Nam Mechanical Company.

Contact information NHAT NAM MECHANICAL CO., LTD: House No. 36, Garland – Phuoc Dien Street, 72 Dinh Hoi Street, Phuoc Long B Ward, District 9, Ho Chi Minh City, Vietnam

Contact Japan

Email: tranquy@cokhinhatnam.vn

Tel: +84 938 771 508

Contact English

Email: marketing@cokhinhatnam.vn

Tel: +84 964 092 079

Contact Vietnam

Email: vinhnt@cokhinhatnam.vn

Tel: +84 964 084 479