1. Introduction

In the sheet metal industry, bending is an extremely common process — used in making electrical cabinets, machine frames, boxes, and small components. However, if the bending rules are not properly followed, the product may crack, warp, end up with incorrect dimensions, or even become unassemblable.

This article summarizes the key principles that technicians, engineers, and machinists need to understand to ensure:

Bends are accurate according to the design.

The material is not damaged.

Production waste is minimized.

2. Bending Radius – Don’t Try to Bend Too Tightly

When bending metal, if you force the sheet into a corner that is too sharp, the outer surface may become overstretched and prone to cracking.

Therefore:

Never bend into a completely sharp (acute) angle with a radius of 0.

The inner radius of the bend should be at least equal to the sheet thickness.

Example: If the sheet is 1 mm thick → the minimum bend radius should be 1 mm.

For harder materials such as stainless steel or aluminum, you should use a bend radius 1.5 to 2 times the material thickness to avoid cracking.

3. Grain Direction – Surface Appearance Matters Too

When metals are rolled at the mill, they develop a “grain” running along their length, similar to wood grain.

If you bend parallel to this grain direction — especially with brittle materials like aluminum — the risk of cracking is much higher.

Principles:

Bending perpendicular to the grain direction creates stronger bends and reduces the risk of cracking.

If the grain is not clearly visible, inspect the surface under light — faint linear marks will indicate the grain direction.

4. Distance from Hole to Bend Edge – Avoid Distortion

If your part includes drilled holes, screw holes, or slots near a bend line, you must consider the following:

Do not place holes too close to the bend.

The minimum distance from the edge of the hole to the bend line should be 2–3 times the sheet thickness.

Example: With a 1.5 mm sheet → holes should be at least 3–4.5 mm away from the bend edge.

Reason: During bending, the area around the hole is stretched and may become distorted or deformed.

5. Bend Length (Edge) – Don’t Make It Too Short

One of the common mistakes in sheet metal design is making the bent edge too short. This can lead to:

The edge popping up, breaking, or deforming.

Not enough surface for the die to grip during bending.

Basic rule:

The minimum bend length (the straight section after the bend) should be at least:

4 × sheet thickness + bend radius

Example:

For a 1 mm thick sheet with a 1 mm bend radius:

→ Minimum edge length = 4 × 1 + 1 = 5 mm

If this rule is not followed, the part may be rejected or the bending process may fail entirely.

6. Elasticity After Bending – It’s Not Always What You Designed

After the bending force is removed, the material tends to spring back slightly. This behavior is called elastic recovery, and it means:

You bend the sheet to 90°, but it returns to 93° after releasing.

Materials like aluminum and stainless steel are more prone to this effect than carbon steel.

How to handle this:

Over-bend slightly: For example, if you want 90°, you bend to 87–88°.

Use a CNC press brake that has automatic angle compensation, which adjusts for springback automatically.

This compensation is especially important when producing precision parts in large batches.

7. Material Elongation – The Hidden Key to Good Bends

This is a critical factor that experienced engineers often consider, especially when dealing with sharp bends or tight radii.

When a sheet metal part is bent, the outer surface stretches. If the material cannot handle this stretch (low elongation), it will:

Crack at the bending line.

Lose structural strength and become unusable.

Tips:

If your design includes sharp bends or tight radii, choose materials with high elongation.

Mild steel and SUS304 stainless steel are excellent for complex bending tasks.

Avoid brittle or hardened materials for parts that require tight bends.

8. Calculate the length of the blank before bending

As a result:

After bending, the final dimensions may be too short or too long.

This leads to significant errors during assembly.

Solution:

It’s important to accurately calculate the amount of material that will be “consumed” or lost during bending.

You can use technical drawing software like AutoCAD or SolidWorks… online bend allowance calculators, or rely on hands-on measurement experience with the same type of material.

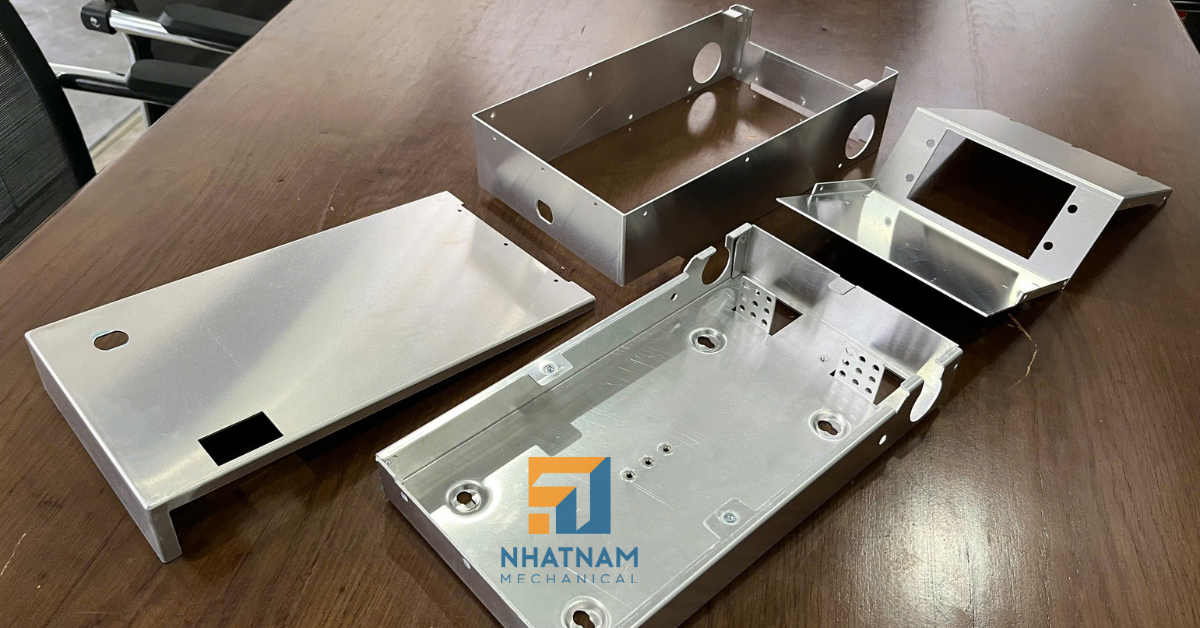

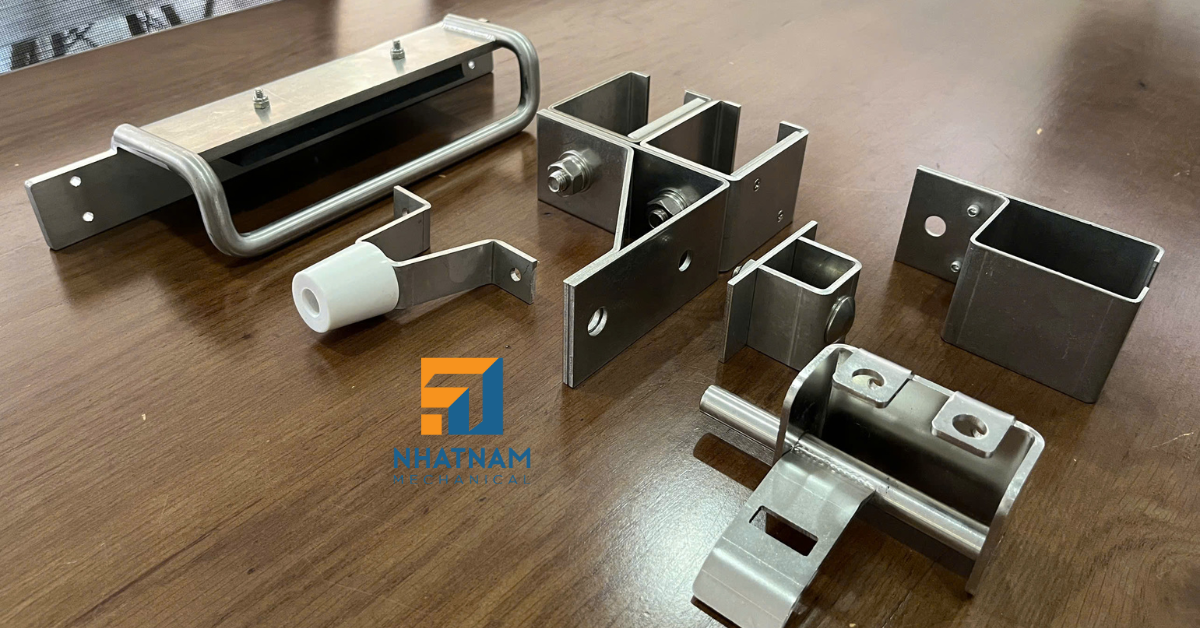

At Nhat Nam Mechanical, we specialize in manufacturing custom metal components and fully understand that:

Even a small error in the bending process can lead to misalignment during fast assembly.

Uncontrolled cracking, deformation, or springback can result in the waste of an entire production batch.

That’s why we always:

Choose the right material to match the required bending radius.

Design drawings with pre-calculated allowances for strength and deformation.

Apply a process of checking elongation, grain direction, and springback angles right from the machine setup stage.

With this approach, we ensure that every product delivered to our customers meets strict standards for precision, aesthetics, and durability. That is also why Nhat Nam Mechanical has become a trusted partner of many domestic and international businesses in the field of precision sheet metal fabrication.