In the field of sheet metal fabrication, welding is a key step in creating products with high durability and good aesthetics.

However, each material — stainless steel, mild steel, and aluminum — has very different properties that directly affect the welding method, equipment used, and weld quality.

Understanding the differences between these three materials helps technicians choose the right technology, while helping businesses save costs and ensure consistent product quality.

1. Stainless Steel Welding

Outstanding Characteristics

Stainless steel has excellent corrosion resistance and retains its shine after welding.

However, it has poor heat conductivity and a high thermal expansion rate, making it prone to warping or discoloration in the weld area if not handled properly.

In addition, since the stainless steel surface easily oxidizes when exposed to hot air, the welding process must be protected with inert gas shielding to prevent tarnishing and maintain corrosion resistance.

Suitable Welding Techniques

TIG welding: produces smooth, bright welds with minimal spatter – ideal for products requiring high aesthetics.

MIG welding: offers faster welding speeds – suitable for high-production applications.

Spot welding: used for joining thin sheets such as electrical cabinets or machine enclosures.

Common Applications

Furniture, railings, electrical cabinets, kitchen equipment, elevators.

Components requiring high gloss, durability, and corrosion resistance.

Notes When Welding

Maintain a stable temperature and avoid overheating the material.

Use pure Argon gas for shielding to prevent oxidation.

Clean the weld after finishing to restore its natural shine.

2. Mild Steel Welding

Outstanding Characteristics

Mild steel is the easiest material to weld, with good thermal conductivity and a low risk of cracking or warping during welding.

Its main drawback is poor corrosion resistance, so the surface must be painted or plated after welding for protection.

Thanks to its stable properties and low cost, mild steel is widely used in mechanical structures, machine frames, and industrial equipment.

Suitable Welding Techniques

MIG welding: produces strong, clean welds with minimal slag – ideal for mass production.

Stick welding (SMAW): flexible and easy to perform on-site.

TIG welding: used for thin parts or when high weld aesthetics are required.

Common Applications

Steel frame structures, work tables, racks, industrial machine frames.

Mechanical components that require high strength and cost efficiency.

Notes When Welding

Clean rust, oil, and grease before welding.

Select the appropriate current according to material thickness.

Apply paint or galvanizing after welding to prevent rust.

3. Aluminum Welding

Outstanding Characteristics

Aluminum is a very lightweight material with high thermal conductivity and natural corrosion resistance, but it is also the most difficult to weld among the three.

Due to its excellent heat conductivity, the weld area can easily overheat, warp, or burn through if not carefully controlled.

Moreover, aluminum has a hard oxide layer on its surface that must be cleaned thoroughly before welding — otherwise, it can cause porosity or weak welds.

Appropriate Welding Techniques

TIG welding (AC mode): ideal for thin aluminum, providing bright, clean welds.

MIG welding: used for thicker aluminum sheets or high-productivity applications.

Use Argon or an Argon–Helium gas mixture for better arc stability.

Common Applications

Car frames, machine housings, control panels, electronic components.

Products that require lightweight, aesthetic design, and corrosion resistance.

Notes When Welding

Remove the oxide layer using a stainless-steel brush dedicated to aluminum.

Adjust the welding temperature properly to avoid warping.

Use filler wire made from the same material to ensure weld strength.

4. Overall Comparison

| Criteria | Stainless Steel | Mild Steel | Aluminum |

|---|---|---|---|

| Welding difficulty | Medium | Easy | Difficult |

| Heat conductivity | Low | Medium | Very high |

| Risk of warping | Medium | Low | High |

| Requires shielding gas | Yes | Yes (MIG/TIG) | Yes |

| Corrosion resistance | Excellent | Poor | Naturally good |

| Aesthetic quality | High | Medium | High |

| Common applications | Stainless steel equipment, cabinets, furniture | Machine frames, steel structures | Aluminum housings, lightweight parts |

5. Conclusion

The three common materials in sheet metal processing — stainless steel, mild steel, and aluminum — have very different properties and welding techniques.

Mild steel is easy to weld and cost-effective, making it suitable for mass production.

Stainless steel offers excellent durability and aesthetics but requires precise technique and temperature control.

Aluminum is the most difficult to weld but provides advantages in weight reduction and natural corrosion resistance.

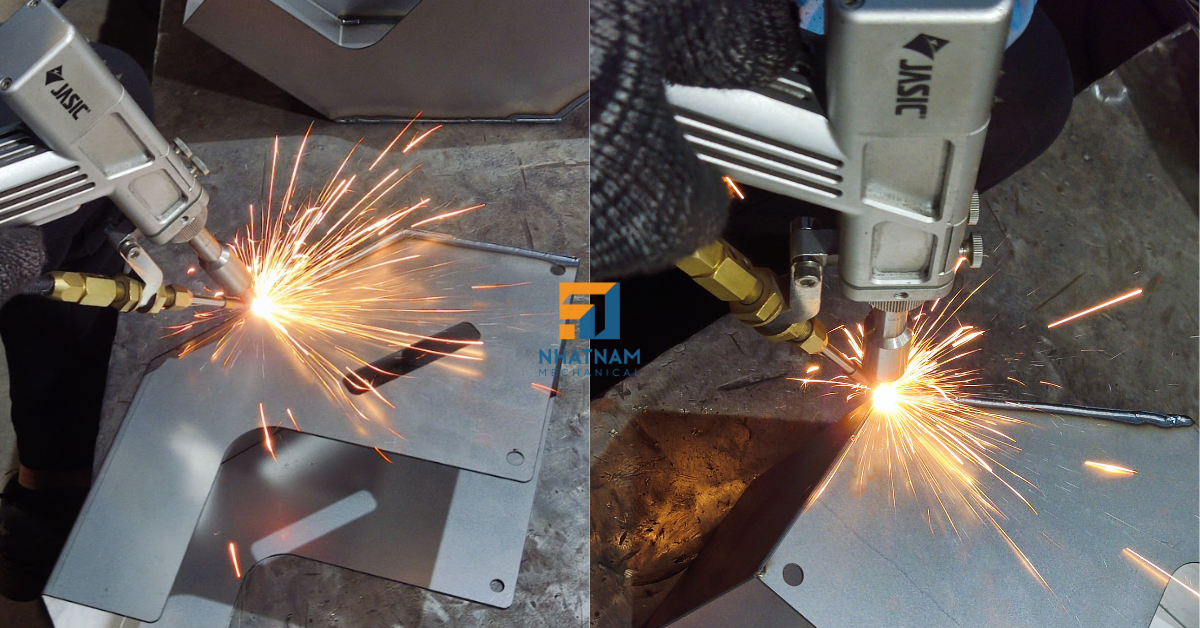

At Nhat Nam Mechanical, our team of highly skilled welders and modern MIG–TIG equipment can handle all types of sheet metal welding, including stainless steel, mild steel, and aluminum.

We deliver strong, clean, and visually appealing welds for industrial projects, interior components, and electronic equipment — ensuring top-quality results that meet technical standards.