From a flat sheet of metal to machine casings, electrical enclosures, automotive parts, and precision components—how does this transformation happen? The answer lies in sheet metal forming operations, including bending, stamping, deep drawing, and more.

At Nhat Nam Mechanical, we specialize in high-precision sheet metal fabrication, offering cutting-edge forming technologies that ensure top-quality results for industries like mechanical engineering, electronics, food processing, pharmaceuticals, and beyond.

SHEET METAL FORMING TECHNIQUES AT NHAT NAM

1. BENDING – PRECISE ANGLES & CLEAN EDGES

Sheet metal bending is essential for forming machine frames, enclosures, electrical cabinets, and structural components. At Nhat Nam, we utilize advanced CNC press brakes to ensure:

- High precision, minimizing warping or misalignment.

- Accurate bending angles, even with tough materials like stainless steel.

- Versatile bending capabilities, from simple shapes to complex geometries.

Common applications:

Industrial machine casings, electrical cabinets, and framework.

Automotive and motorcycle parts, electronic enclosures.

Custom mechanical components requiring high durability.

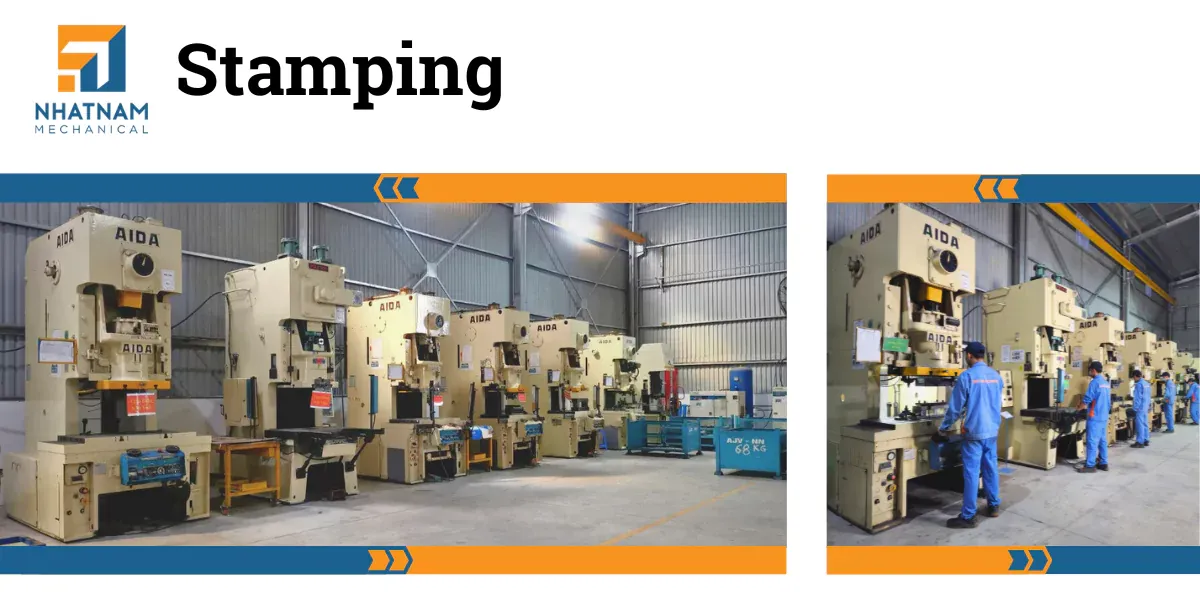

2. STAMPING – HIGH-SPEED, HIGH-PRECISION MASS PRODUCTION

Sheet metal stamping is an efficient technique for large-scale production, delivering consistent, high-accuracy components at high speed.

At Nhat Nam, our state-of-the-art stamping machines offer:

- Mass production efficiency with minimal material waste.

- Lower manufacturing costs, ideal for bulk orders.

- Capability to handle various materials, including steel, aluminum, and stainless steel.

Common applications:

Electronic components, device enclosures.

Automotive chassis parts, industrial brackets.

Hinges, metal connectors, and precision hardware.

3. DEEP DRAWING – SEAMLESS, HIGH-STRENGTH COMPONENTS

Deep drawing is a specialized process for manufacturing seamless, cup-shaped, or cylindrical metal components without requiring welding or assembly.

We produce deep-drawn parts with superior precision, suitable for industries such as:

- Automotive (fuel tanks, exhaust components).

- Food & beverage (stainless steel cookware, storage tanks).

- Medical & electronics (device casings, surgical instruments).

WHY CHOOSE NHAT NAM FOR SHEET METAL FORMING?

Cutting-edge CNC machinery – Ensuring high precision and minimal defects.

- Extensive industry experience – Skilled engineers with deep material knowledge.

- Flexible production – Handling small batches to large-scale manufacturing.

- Expert consultation – Assisting with design optimization and cost-efficient fabrication.

At Nhat Nam, we are committed to delivering the highest quality metal forming solutions, helping clients reduce costs and enhance product performance.

Contact Japan

Email: tranquy@cokhinhatnam.vn

Tel: +84 938 771 508

Contact English

Email: marketing@cokhinhatnam.vn

Tel: +84 964 092 079

Contact Vietnam

Email: vinhnt@cokhinhatnam.vn

Tel: +84 964 084 479

Don’t settle for slow, costly, or inaccurate bending. Get in touch today and experience the difference of precision metal bending done right!