If you have ever manufactured a metal product – from electrical cabinets and machine frames to iron doors and interior tables and chairs – you will certainly understand one thing: paint is not just for aesthetics; it determines the lifespan of the entire product.

In reality, many products fade after just a few months of use, with paint peeling or rust forming from the inside, causing customers to complain that “it’s not the same as when it was first delivered.” This usually stems from choosing the wrong type of powder coating from the start. That is also why this article was created – to share the most popular types of powder coating today, along with guidance on selecting the right one before mass production.

What is powder coating?

Powder coating – a familiar term, but not everyone fully understands it. This method involves applying dry powder onto a metal surface using electrostatic attraction, then placing it in a furnace so the powder melts and adheres tightly to the surface.

Compared to traditional water-based paint, powder coating offers many advantages: higher durability, excellent anti-rust and anti-corrosion properties, better scratch resistance, environmentally friendly, and more uniform, attractive colors. However, one thing often overlooked is that not all powder coatings are the same.

1. Epoxy Powder Coating – the “king” of indoor anti-rust protection

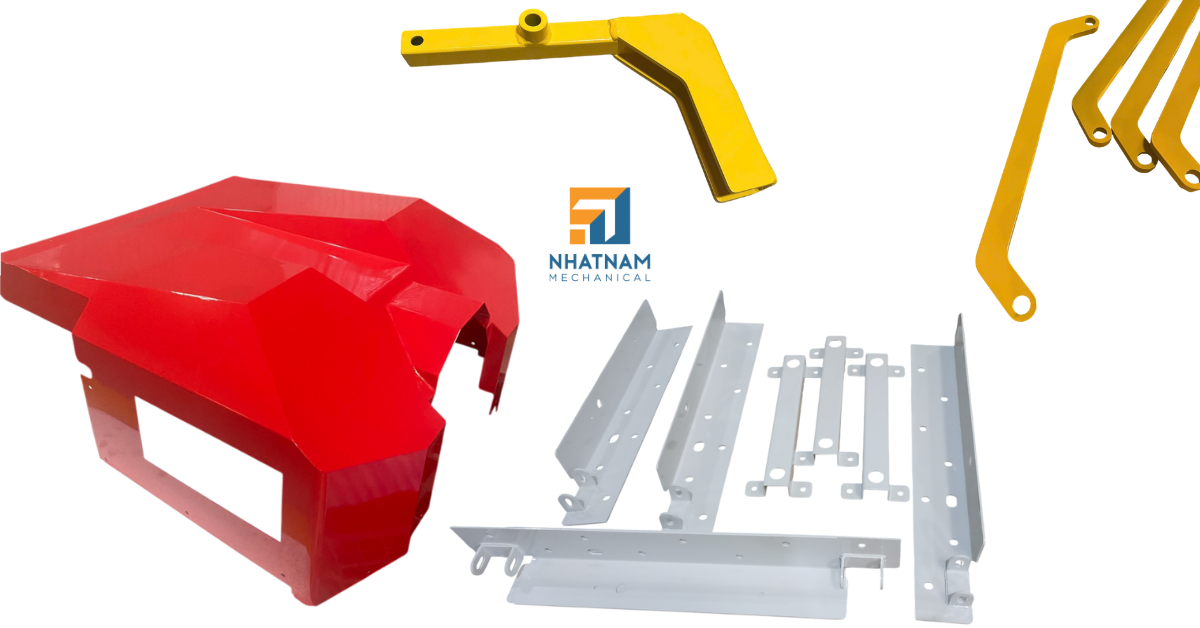

This type of coating is widely used for electrical cabinets, industrial machine housings, steel frames in factories, iron shelves, and warehouse racks.

Epoxy adheres exceptionally well, resists rust, and is highly chemical-resistant. For indoor products not exposed to sunlight or rain, or in environments with grease or chemicals, Epoxy is a great choice at a reasonable price.

However, Epoxy has very poor UV resistance; if used outdoors, it fades quickly, yellows, and becomes brittle. Therefore, it should never be used for outdoor applications.

2. Polyester Powder Coating – the number one choice for outdoor use

For products placed outdoors – such as on balconies, gates, fences, outdoor electrical cabinets – Polyester is almost always the mandatory choice.

Strengths: excellent resistance to sun and rain, minimal fading, fairly scratch-resistant, and long outdoor lifespan.

In fact, most iron gates, railings, fences, roof frames, and civil steel structures use Polyester. With proper paint selection and surface treatment, products can last 10–15 years while remaining stable.

3. Epoxy–Polyester Hybrid – the economical solution

This intermediate coating combines the strong adhesion of Epoxy with the relative color durability of Polyester.

It is usually applied to iron shelves, filing cabinets, office furniture, and indoor metal products.

For products in dry environments, not directly exposed to sunlight or rain, and without demanding exterior requirements, this is an economical choice – sufficient for use and easy to produce.

4. Polyurethane (PU) Powder Coating – for “high-end” products

PU coatings provide a very smooth, attractive surface with high mechanical strength, good scratch and impact resistance.

They are often used for high-end metal furniture, medical equipment, decorative items, and machine housings requiring high aesthetics.

Drawbacks: higher cost and stricter painting process requirements, but the quality difference is immediately noticeable.

5. Acrylic Powder Coating – “mirror” gloss

Acrylic is rarely used in mass production but is important for automotive parts, high-end equipment housings, and products requiring mirror-like gloss.

Characteristics: extremely high gloss, good outdoor color retention, and a luxurious appearance.

Drawbacks: high cost, generally used only when customers have specific requirements.

6. Effect Powder Coating – when aesthetics are the priority

This category includes hammer-pattern, sandblasted, wood imitation, metallic–glitter, and anti-fingerprint coatings. It is often used for interior furnishings, showrooms, display shelves, and custom-designed products, with the main goal of creating unique aesthetics.

Powder Coating Services at Nhat Nam Mechanical Engineering – done right from the start

In real production, issues such as peeling, fading, and rust often arise shortly after use. Most causes are not the paint itself but surface preparation and temperature control during painting.

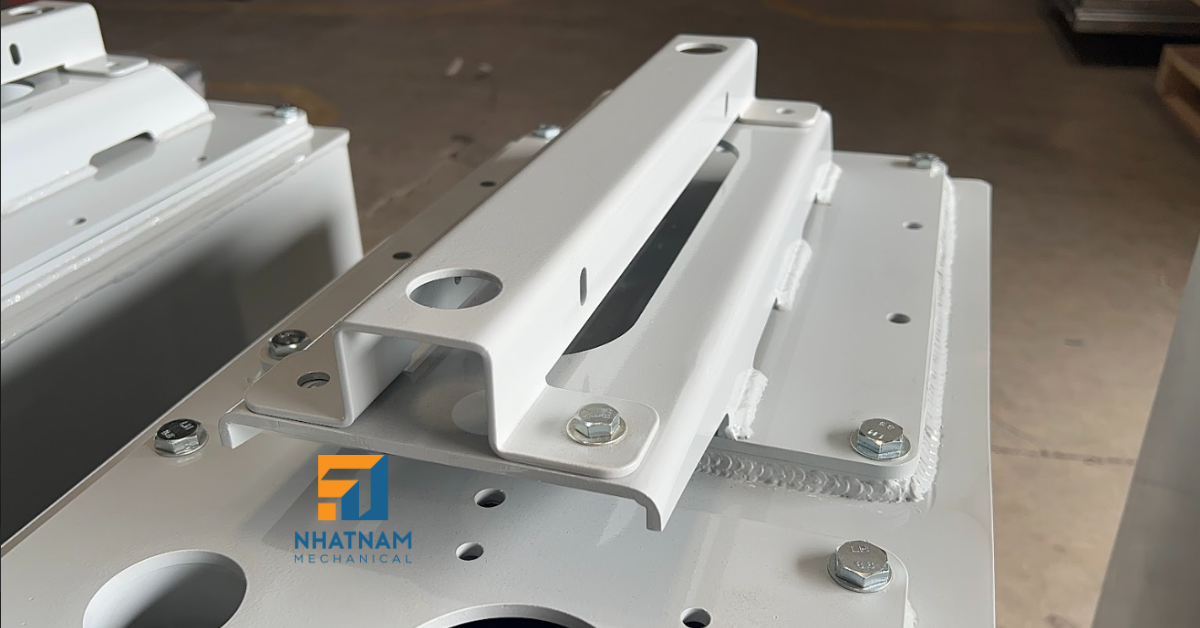

At Nhat Nam Mechanical, electrostatic painting services follow a strict process:

- Thorough surface treatment: degreasing, rust removal, chemical treatment or sandblasting

- Selecting the right type of coating based on the environment: Epoxy, Polyester, PU, effect coatings, etc.

- Controlling paint layer thickness and maintaining stable furnace temperatures

- Checking adhesion, coverage, and surface quality before delivery

As a result, Nhat Nam-painted products are:

- Durable with difficult-to-peel paint

- Rust-resistant

- Smooth, uniform, and highly aesthetic

- Suitable for both indoor and outdoor use

Currently, Nhat Nam provides electrostatic painting services for electrical cabinets, machine housings, machine parts, steel frames, and custom sheet metal fabrication products.

If you need a unit capable of both sheet metal fabrication and electrostatic painting with stable quality and easy progress control, Nhat Nam Mechanical is a reliable choice.