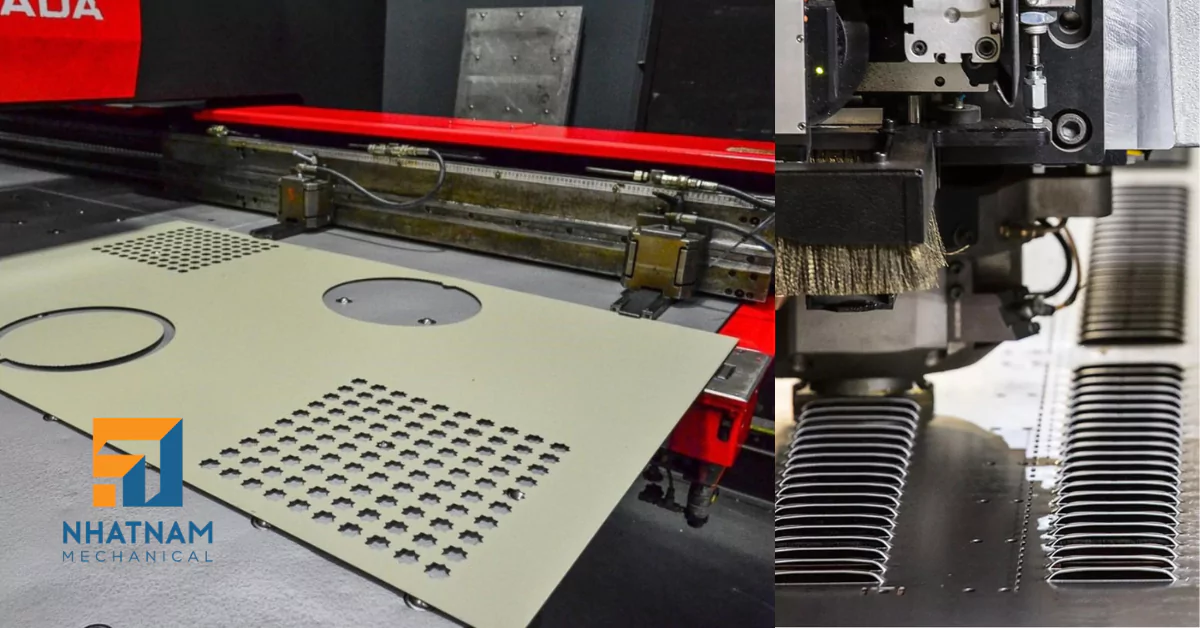

In the era of advanced technology, the demand for precise, durable metal components is growing across various industries. CNC punching services (Computer Numerical Control) have become indispensable, enabling businesses in sheet metal fabrication to optimize production processes, enhance product quality, and accelerate project completion.

Why CNC Punching is the Top Choice in Sheet Metal Fabrication?

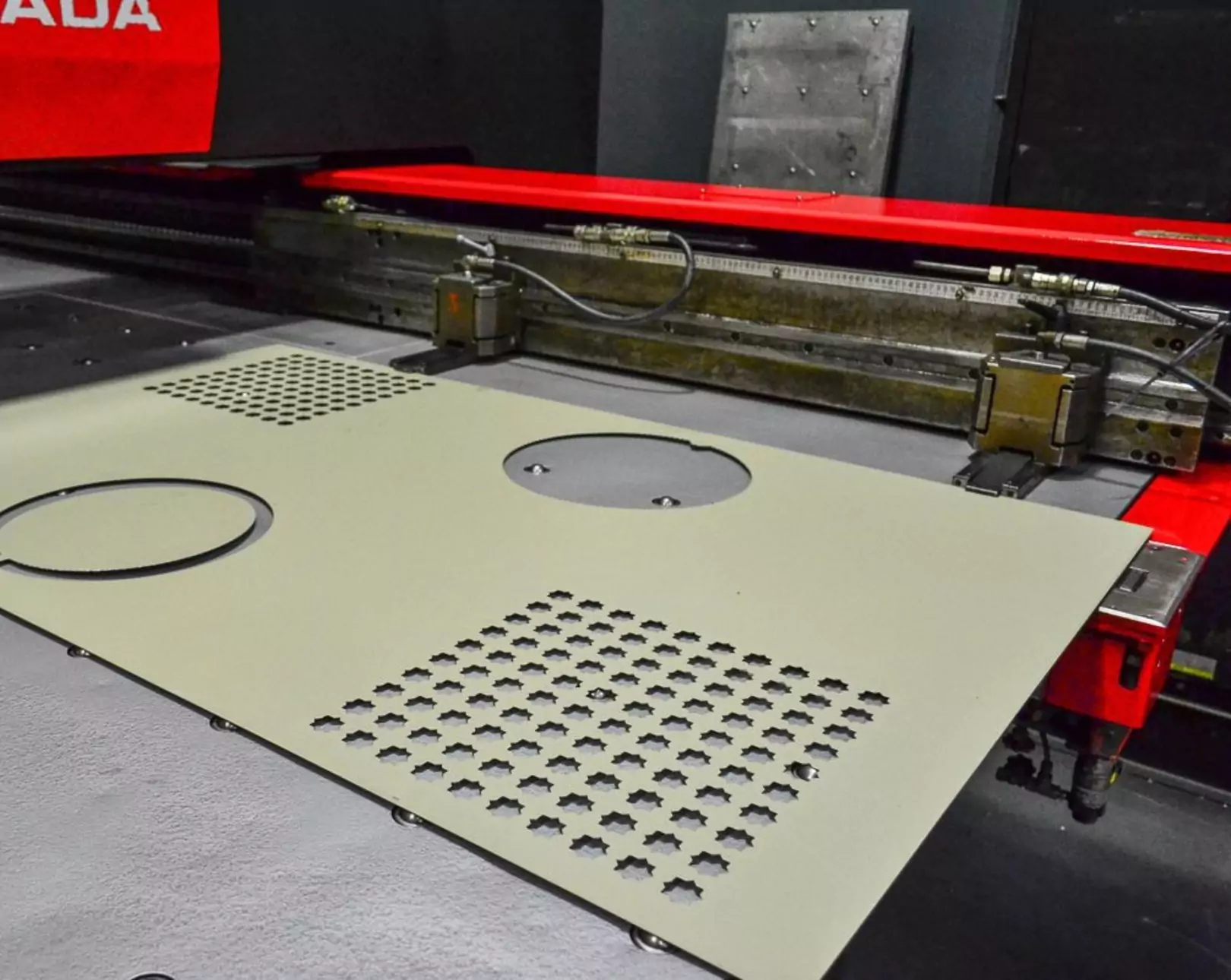

High Precision Down to the Smallest Detail: With CNC technology, each punching operation is pre-programmed for extreme precision, minimizing technical errors. This is crucial for producing parts that require tight tolerances, as needed in electronics, automotive, and aerospace industries.

Enhanced Speed and Production Efficiency: CNC punching allows for continuous, rapid production that meets large-scale requirements without compromising quality. This automation shortens production times, enabling businesses to handle urgent orders flexibly.

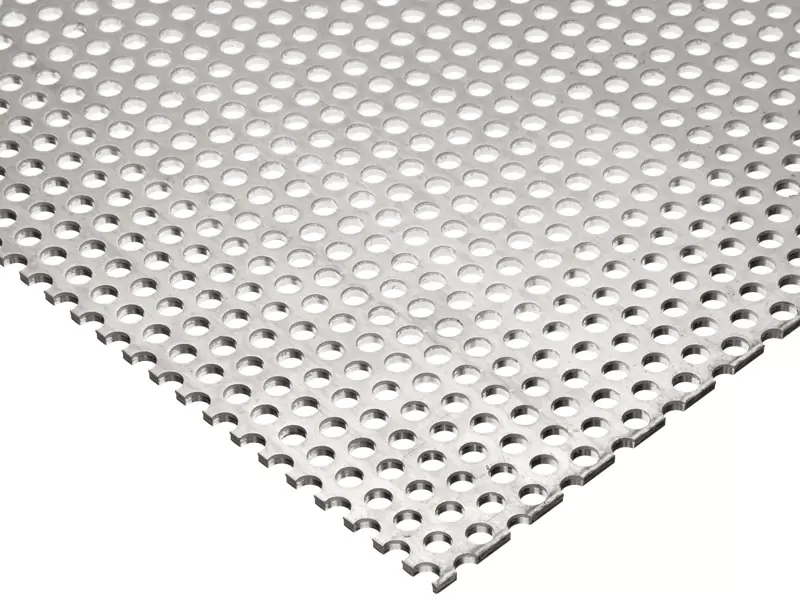

Versatile in Design and Material Compatibility: One of CNC’s key advantages is its ability to process diverse materials like stainless steel, aluminum, copper, and various alloys. CNC punching can produce simple to complex shapes, making it ideal for unique design needs.

Cost Savings and Resource Efficiency: Compared to traditional methods, CNC punching reduces labor needs and optimizes material usage, especially beneficial for high-volume orders. This cost-effective solution provides long-term financial benefits for businesses.

Diverse Applications of CNC Punching in Different Industries

CNC punching is now a vital solution across various industries:

- Automotive Industry: With stringent accuracy and durability requirements, CNC punching produces high-quality engine parts, frames, and other automotive components.

- Electronics Industry: It is used to produce protective casings, shields, and complex metal components.

- Construction Industry: CNC punching is used for metal components in construction projects, from structural framing to decorative interior elements.

- Aerospace Industry: CNC punching creates lightweight, high-strength parts that meet the strict durability and safety standards of aerospace applications.

CNC Punching: A Modern Solution for All Sheet Metal Fabrication Needs

With superior precision, speed, and cost-effectiveness, CNC punching services are the leading choice for projects demanding high quality and detail. Automation helps businesses optimize production, reduce waiting times, and increase productivity.

- Absolute Precision: CNC punching creates components with tight tolerances while minimizing waste.

- Enhanced Efficiency: Modern CNC systems operate continuously, enabling businesses to save time and cost on every project.

- Increased Production Flexibility: No longer limited by complex processes, CNC punching allows businesses to meet various design and functional requirements.

CNC Punching Process – Ensuring Quality from Start to Finish

- Requirement Analysis and Design: Technicians gather client requirements to understand design and technical specifications.

- Programming and Testing: After finalizing the design, specifications are programmed into the CNC system to ensure precision during punching.

- Manufacturing and Quality Control: During punching, products undergo step-by-step inspections to ensure they meet customers’ stringent requirements.

Why Choose Our Punching Services?

- Guaranteed Quality and Reputation: As a top-rated metal fabrication service, each processed component undergoes rigorous inspection, ensuring the highest standards.

- Professional Team: Our experienced technicians ensure smooth, accurate processing, ready to support clients’ requirements.

- Meeting Diverse Needs: From small projects to large-scale production, CNC punching is adaptable and efficient.

The metal punching method is becoming an indispensable solution in modern industrial production, thanks to its accuracy, efficiency, and flexibility.

At Nhat Nam, we take pride in being a leading unit in the field of metal punching with advanced technology. With a team of experienced engineers and a fully automated process, we are committed to delivering high-quality products that quickly and flexibly meet all customer requirements. Contact us to learn more about metal processing services at Nhat Nam Mechanical Company.

NHAT NAM MECHANICAL CO., LTD contact information: House No. 36, Garland – Phuoc Dien, 72 Duong Dinh Hoi, Phuoc Long B Ward, District 9, Ho Chi Minh City, Vietnam

Contact Japan

Email: tranquy@cokhinhatnam.vn

Tel: +84 938 771 508

Contact English

Email: marketing@cokhinhatnam.vn

Tel: +84 964 092 079

Contact Viet Nam

Email: vinhnt@cokhinhatnam.vn

Tel: +84 964 084 479