INTRODUCTION

Quality control is vital step involves detailed inspections, rigorous testing, and consistent validation throughout production to catch defects, ensure uniformity, and provide outcomes you can depend on. Using advanced tools and trusted techniques, we evaluate materials, dimensions, and finishes to meet your exact specifications while adhering to globally recognized standards like ISO 9001:2015, BIFMA/ANSI, and RoHS.

At Nhat Nam, we offer exceptional quality control services adapted to your unique requirements. With skilled experts and modern technology, we provide thorough solutions for industries ranging from manufacturing to product development and beyond. Our team delivers high quality in every step.

Type Of Services

With our expertise and robust capabilities, we provide a wide range of quality control services, organized to meet your specific requirements:

Mechanical Testing

- Tensile Strength Testing: Measures a material’s resistance to pulling forces, confirming durability.

- Hardness Testing: Evaluates resistance to deformation, ensuring material strength.

- Impact Testing: Tests toughness under sudden impacts for reliable performance.

- Corrosion Testing: Assesses resistance to rust and wear over time.

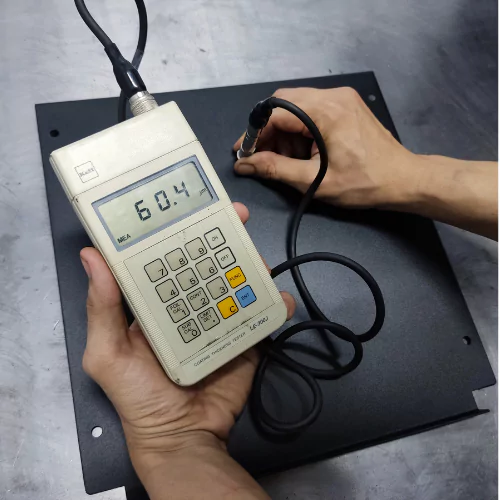

Surface and Coating Measurement

- Gloss Measurement: Checks surface shine with a gloss meter for consistent finish quality, aligned with BIFMA/ANSI aesthetic standards.

- Coating Thickness Measurement: Measures plated or painted layer thickness for durability and compliance with RoHS hazardous substance limits.

Inspection and Verification

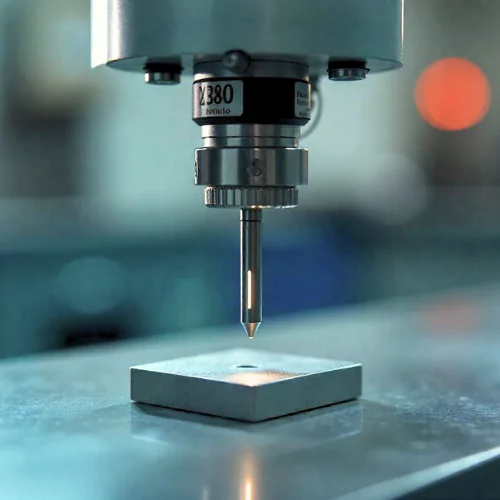

- Dimensional Inspection: Confirms parts align with design specs, including precise dimension and freedom from non technical defective, using tools like calipers, height measuring instruments, ultrasonic welding equipment, etc to meet BIFMA/ANSI performance criteria.

- Surface Quality Check: Examines finishes for defects and uniformity, ensuring adherence to standards.

- Final Product Validation: Verifies finished goods meet all specs and certifications like RoHS before delivery.

CAPABILITIES

Our proficient quality control specialists bring keen insight and deep experience to every project, leaving no detail overlooked. We leverage reliable, high-precision equipment to conduct a broad spectrum of inspections and tests - from dimensional accuracy to material performance - with unwavering consistency. Certified to ISO 9001:2015, our processes reflect a commitment to quality management excellence, ensuring systematic and repeatable results. Whether you need a focused check or a full quality assessment, we adjust our approach to suit your objectives, giving you confidence that your products meet both functional demands and regulatory standards like RoHS and BIFMA/ANSI.

Certifications and Standards

We pride ourselves on meeting and exceeding industry benchmarks:

- ISO 9001:2015: Our quality management system follows this international standard, emphasizing continuous improvement, customer satisfaction, and riskbased thinking.

- BIFMA/ANSI Standard: We ensure products meet rigorous safety, durability, and sustainability benchmarks set by the Business and Institutional Furniture Manufacturers Association and the American National Standards Institute.

- RoHS Certification Services: We verify compliance with the Restriction of Hazardous Substances directive, limiting harmful materials like lead and mercury in electronic components for safer, eco-friendly products.

FAQs

What materials do you inspect?

We handle metals like steel, aluminum, and alloys, plus other materials as needed.

How long does quality control take?

It depends on project scope, but we prioritize speed without cutting corners.

Can you align with specific standards like ISO or RoHS?

Yes! We adapt our services to meet your chosen standards—just tell us your needs.

What industries do you support?

We serve OEM, automotive, aerospace, furniture, electronics, and more.

Why Chose Us?

Our dedicated experts work closely with you every step of the way to design, develop, and deliver the precision-crafted part and customized product.

With ISO 9001 Certification and ANSI Certification, only the top shops that apply to become network suppliers make it through our qualification process.

Our team of Application Engineers and Process Specialists are available to support you and provide answers to all of your fabrication and manufacturability questions.