Introduction

What is Metal Fabrication Machinery?

Metal fabrication combines precision engineering principles to transform raw materials into finished products. Manufacturing process requires careful attention to detail at every step, especially during the forming stages, which is crucial to achieving a durable and efficient final product.

At Nhat Nam Mechanical, we use reliable mechanical cutting and bending processes to fabricate components that ensure smooth assembly and reliable operation.

Process

From Precision Cutting to Perfect Assembly

Metal Fabrication Machinery requires careful attention to detail in every step, especially during the cutting and bending stages.

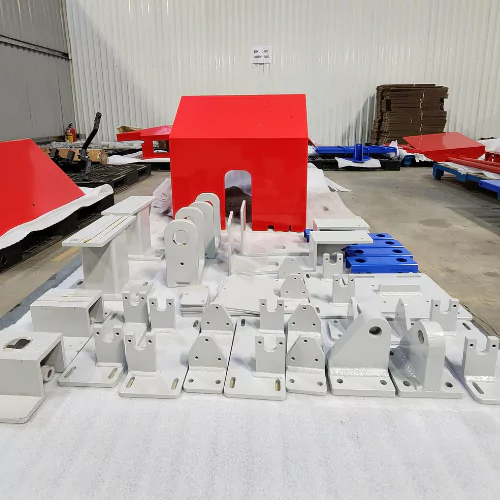

1. Mechanical Cutting for Precise Component Preparation

Consistency: Each cut is performed with precision to meet the required specifications.

Material Flexibility: Our equipment handles a wide range of materials suitable for Metal Fabrication Machinery components.

Reduced Deformation: Mechanical cutting applies controlled force, minimizing material distortion and preserving structural integrity.

2. Bending for Strong and Reliable Components

Structural Integrity: Controlled bending angles that enhance load-bearing capacity and durability.

Accurate Dimensions: Consistent quality to facilitate smooth assembly and operation.

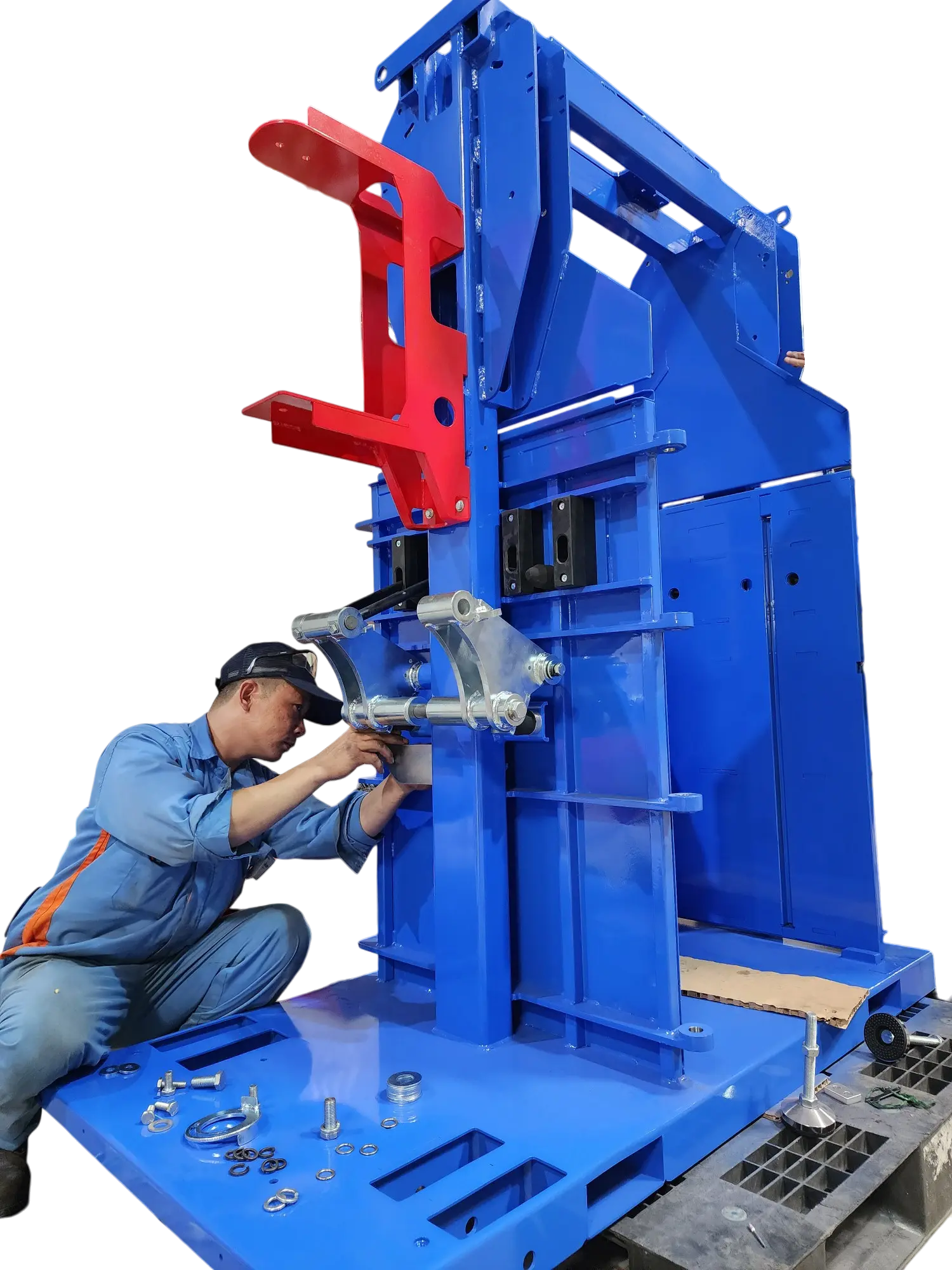

3. Careful Assembly Turning Components into Functional Machines

Precise Fitting: : Each component is carefully assembled to avoid any technical errors during operation

Quality Checks: Every detail, from screws to component alignment, is meticulously inspected to provide flawless assembly and consistent performance.

Benefits

Benefits of Nhat Nam's OEM Metal Fabrication Machinery Services

1. Precision Components for High-Quality Performance

Each machine is manufactured using advanced cutting, bending and welding processes, offering the following advantages:

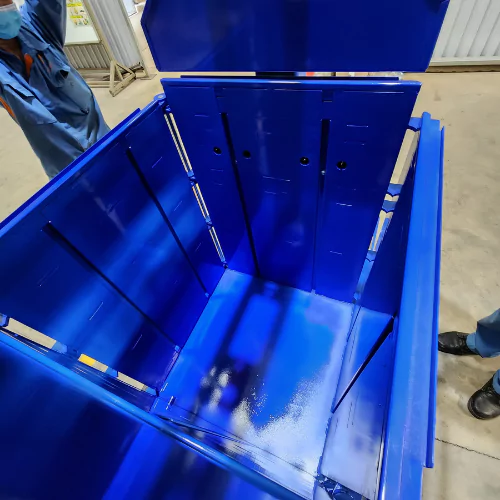

Precise Fit: Components are manufactured with high precision, ensuring smooth assembly and operation.

Reduced Downtime: High-quality components help minimize failures, keeping your production running efficiently.

2. Seamless assembly for trusty operation

Our assembly process guarantees that every part works perfectly:

Perfect synchronization: All components are assembled precisely, from the large tank to the small details such as wheels and handles, ensuring that everything works together perfectly. Thoroughly tested: Each machine undergoes a component-by-component inspection and is tested multiple times before being delivered to the customer.

3. Professional technical support and service capabilities

With over 9 years of experience in manufacturing and processing sheet metal for partners ranging from local businesses to global enterprises. We specialize in large-scale industrial equipment, including heavy-duty metal fabrication machinery. We are committed to providing dependable solutions so that our customers operate with confidence-free from concerns about technical issues, quality, or service.

Why Chose Us?

Our dedicated experts work closely with you every step of the way to design, develop, and deliver the precision-crafted part and customized product.

With ISO 9001 Certification and ANSI Certification, only the top shops that apply to become network suppliers make it through our qualification process.

Our team of Application Engineers and Process Specialists are available to support you and provide answers to all of your fabrication and manufacturability questions.

Have an upcoming project?

Nhat Nam Factory

245 Phan Dang Luu, Tan Cang, Phuoc Tan, Bien Hoa, Dong Nai, Vietnam.

Email us

cokhinhatnam.info@gmail.com

Call us

(+84) 964 092 079 (EN) (+84) 964 084 479 (VN) (+84) 938 77 15 08 (JPN)