Introduction

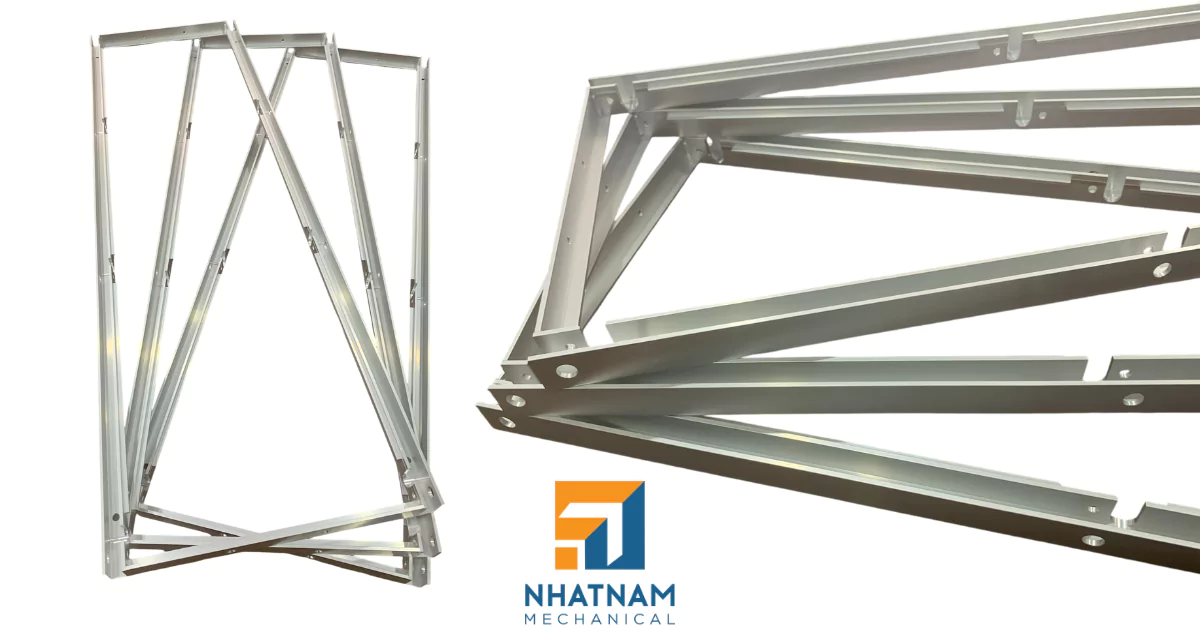

Aluminum frames are structures made from aluminum, commonly used as frames for doors, windows, partitions, or other structures in construction and industry. Aluminum is a material known for its high durability, light weight, excellent corrosion resistance, and ease of fabrication, making aluminum frames popular in various applications.

An aluminum frame project typically involves the design, fabrication, and installation of structures using aluminum as the primary material for framing. These frames are widely used in industries such as construction, automotive, aerospace, and manufacturing due to aluminum's advantageous properties

Common Applications of Aluminum Frames:

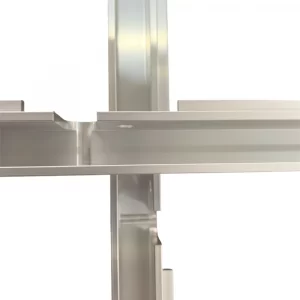

Aluminum doors and windows: Aluminum is often used as the frame for windows and entrance doors, especially in modern buildings and residential homes.

Aluminum-glass partitions: Aluminum frames combined with tempered glass create aesthetic partitions, providing open and modern spaces for offices and homes.

Industrial aluminum frames: Aluminum is used to make frames for equipment and machinery due to its strength, durability, and ease of assembly.

Benefits of Aluminum Frames:

Aluminum frames offer several key benefits that make them a popular choice across various industries, including construction, automotive, and manufacturing:

- Lightweight: Allows for easy transportation and installation.

- Corrosion resistance: Aluminum does not rust when exposed to water or other environmental factors.

- Low maintenance: Aluminum frames require minimal upkeep, remaining clean and durable over time.

- Aesthetic appeal: They can be coated in various colors, making them suitable for different interior and exterior designs.

Process: aluminum frame fabrication step to step

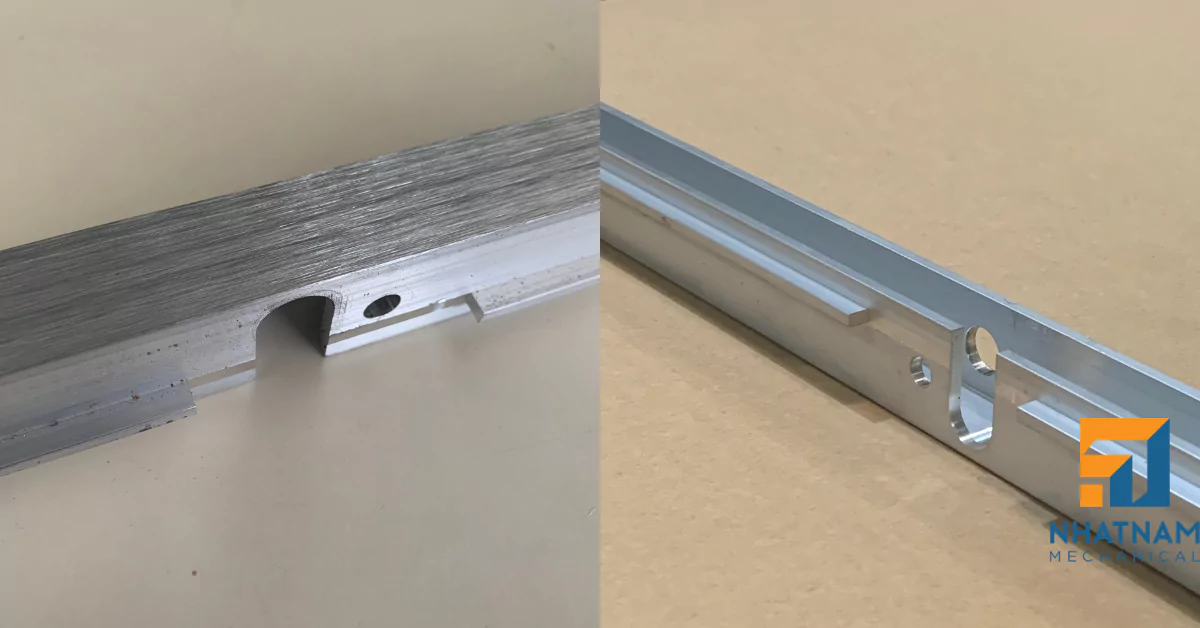

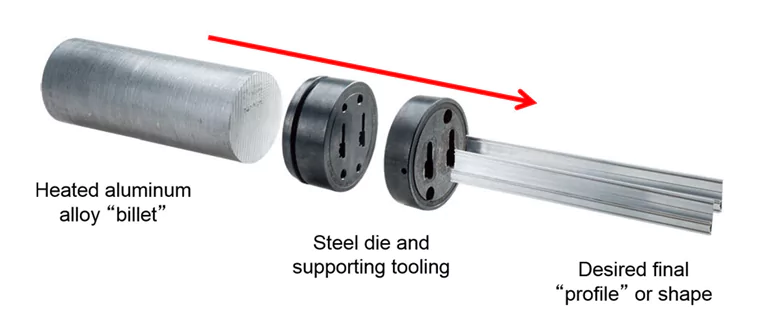

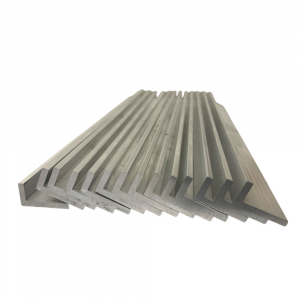

Aluminum Extrusion Method

The extrusion method is a process of manufacturing aluminum by heating aluminum billets to a temperature range of 700 – 900 degrees Fahrenheit. The heated billets are then pushed through a steel die using high pressure to create the desired aluminum cross-sectional shapes. After extrusion and cutting to size, the aluminum profiles are aged to increase hardness and mechanical strength.

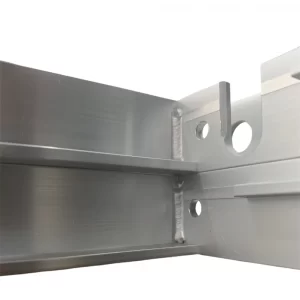

Aluminum fabrication

Common Methods of Aluminum Machining

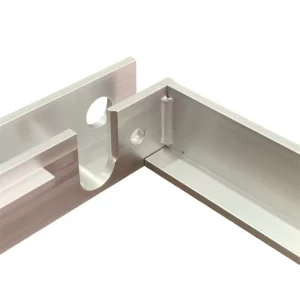

Aluminum machining involves shaping, cutting, and carving metal products from aluminum billets using cutting tools such as lathes, milling machines, drills, saws, and grinders. This method ensures that products achieve the desired dimensions and shapes.

For optimal performance in aluminum machining, in addition to selecting the appropriate cutting materials, it is important to use suitable lubricants and coolants:

CNC Laser Cutting Method

CNC laser cutting uses a powerful laser beam to cut through aluminum sheets, creating aluminum products with high precision and smooth surfaces. This technology offers flexibility and fast machining speeds.

Aluminum Laser Welding Method

Laser welding of aluminum is a process of joining aluminum parts using a laser beam. This process focuses high temperature on the welding area, melting the aluminum surface and combining them as the material solidifies.

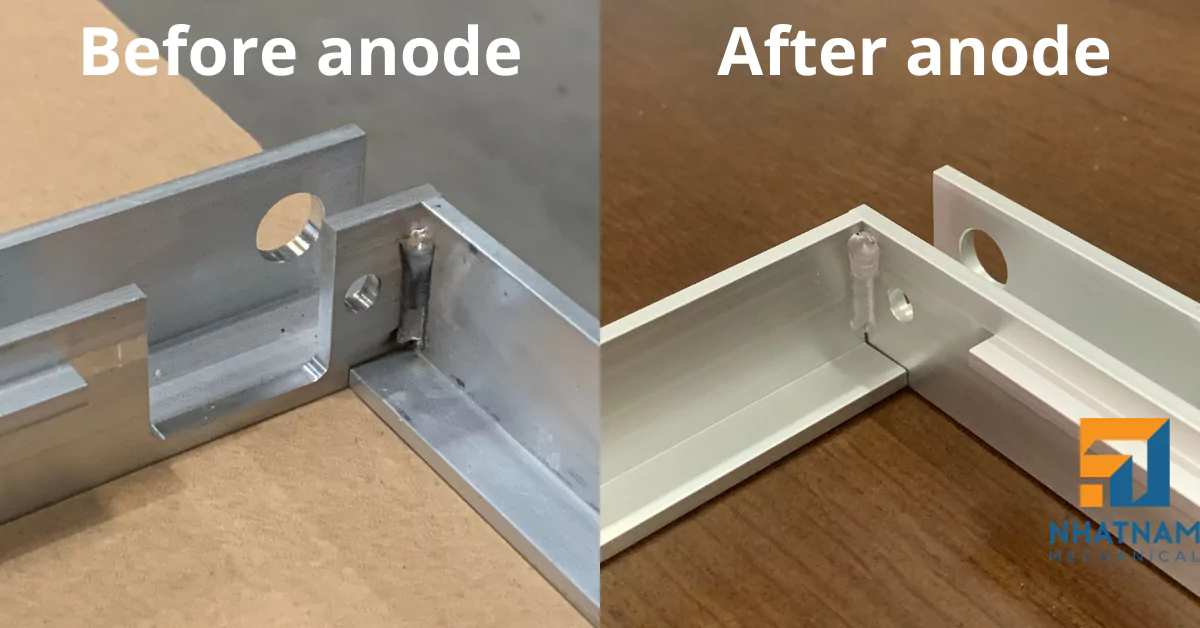

Anodizing Aluminum Method

In simple terms, anodizing aluminum is the process of immersing aluminum parts in an electrolytic solution (the electrolytic solution can be sulfuric acid or chromic acid). Chemical reactions occur, creating a thin layer of aluminum oxide on the surface of the aluminum part (measured in micrometers). This oxide layer is very hard and offers excellent corrosion and wear resistance.

A unique feature of this oxide layer is its ability to absorb colors well, resulting in products with diverse colors. Therefore, anodizing technology is increasingly favored and applied in many industries such as construction, electronics, automotive manufacturing, and household appliances.

Benefits and Applications of Anodized Aluminum:

Benefits:

- Increased Durability: The oxide layer creates a protective surface, enhancing corrosion and wear resistance.

- Aesthetic Appeal: Anodizing aluminum results in a brighter and more attractive surface.

- Hardness: The surface of aluminum becomes harder after anodizing.

In addition to metal fabrication services, NHAT NAM MECHANICAL also meticulously inspects with testing equipment to ensure quality for your project. All products delivered to customers are carefully packaged and promptly shipped.

Why Chose Us?

Our dedicated experts work closely with you every step of the way to design, develop, and deliver the precision-crafted part and customized product.

With ISO 9001 Certification and ANSI Certification, only the top shops that apply to become network suppliers make it through our qualification process.

Our team of Application Engineers and Process Specialists are available to support you and provide answers to all of your fabrication and manufacturability questions.

Have an upcoming project?

Nhat Nam Factory

245 Phan Dang Luu, Tan Cang, Phuoc Tan, Bien Hoa, Dong Nai, Vietnam.

Email us

cokhinhatnam.info@gmail.com

Call us

(+84) 964 092 079 (EN) (+84) 964 084 479 (VN) (+84) 938 77 15 08 (JPN)