In today’s competitive manufacturing landscape, precision sheet metal prototyping plays a crucial role in bridging the gap between design concepts and full-scale production. For both OEM manufacturers and companies with custom sheet metal fabrication needs, the ability to produce accurate, high-quality prototypes is key to achieving product excellence and reducing time-to-market.

What is Precision Sheet Metal Prototyping?

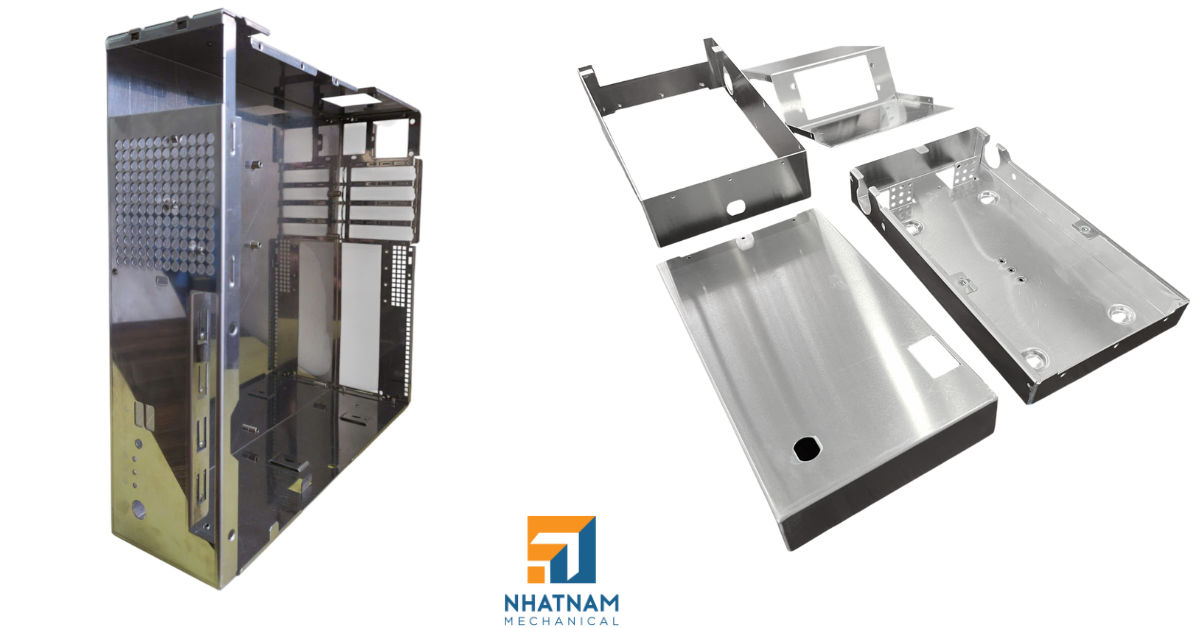

Precision sheet metal prototyping is the process of creating an accurate, functional model of a part or assembly before mass production. This stage allows engineers and designers to test the fit, function, and manufacturability of a design, ensuring every detail meets strict quality standards.

From complex enclosures for electronics to custom brackets for machinery, prototyping enables manufacturers to validate designs, identify improvements, and eliminate costly errors before scaling up production.

Why OEM Projects Rely on Prototyping

OEM projects often demand large-scale production runs with consistent quality across every part. Prototyping offers OEMs the opportunity to:

Refine designs based on real-world testing.

Ensure compatibility with existing systems or assemblies.

Meet tight tolerance requirements essential for high-volume manufacturing.

With precision prototyping, OEMs can confidently approve designs for mass production, knowing that all specifications have been verified.

Custom Fabrication Benefits

For custom fabrication projects—where every order may be different—prototyping is even more valuable. It allows for:

Tailored designs that meet unique customer requirements.

Shorter lead times by resolving design issues early.

The flexibility to test different materials, finishes, and coatings (including powder coating or anodizing).

Advanced Capabilities in Prototyping

At Nhat Nam Sheet Metal, we combine advanced CNC machinery, laser cutting, bending, and welding capabilities to deliver precise prototypes quickly. Our engineering team works closely with clients to:

Interpret CAD files and technical drawings accurately.

Suggest cost-effective manufacturing methods.

Maintain quality control from initial concept to final prototype.

We also offer surface finishing options to simulate the final product look and performance, giving clients a true-to-life preview before production.