In the modern sheet metal fabrication industry, production efficiency is measured not only by output but also by accuracy, processing speed, and cost per product. CNC sheet metal punching machines have become one of the key solutions helping businesses optimize their entire production process.

1. High Accuracy – The Foundation of Product Quality

CNC punching machines operate based on numerical control programs, allowing precise control of each punching position, hole size, and distance between features. Compared to traditional punching methods, errors are minimized and are almost independent of operator skill.

Thanks to high precision:

Punching details achieve absolute uniformity across production batches

Misalignment of holes, large burrs, and sheet deformation are significantly reduced

Precise assembly requirements for electrical cabinets, machine frames, and mechanical components are easily met

This level of accuracy is especially important for products that require high repeatability in mass production.

2. Fast Processing Speed – Shorter Production Time

One of the biggest advantages of CNC punching machines is their superior processing speed. The machine can continuously perform multiple punching operations within a single program, without the need to stop for manual adjustments.

The benefits of high-speed processing include:

Shorter setup times compared to mechanical or semi-automatic machines

The ability to punch hundreds to thousands of holes in a short period

Suitability for both high-volume orders and products with complex designs

As a result, production lead times are reduced, helping businesses meet urgent orders and ensure on-time delivery.

3. Optimized Production Costs – Reduced Waste, Increased Efficiency

Investing in CNC punching machines not only delivers technical advantages but also helps optimize overall production costs in the long term. With high accuracy and flexible programming, material utilization is improved and waste is minimized.

Specifically:

Material waste caused by machining errors is reduced

Repair and rework costs are minimized

Dependence on highly skilled manual labor is lowered

Punch layouts can be easily optimized to maximize sheet metal utilization

By effectively controlling the cost per part, businesses gain a significant competitive advantage while maintaining consistent product quality.

4. High Flexibility in Production

CNC punching machines allow for rapid program changes, making them well suited to diverse orders and on-demand production. By simply adjusting input data, the machine can process a wide variety of parts without major equipment changes.

This flexibility enables businesses to:

Easily switch between different product models

Adapt to the growing demand for customized components

Enhance competitiveness in the sheet metal fabrication market

5. Improved Overall Production Line Efficiency

When integrated into a sheet metal processing line, CNC punching machines help create a stable and consistent production flow. Parts produced after punching achieve high accuracy, significantly reducing the need for secondary adjustments during bending, welding, or assembly.

This not only saves time but also improves the overall efficiency of the entire production system.

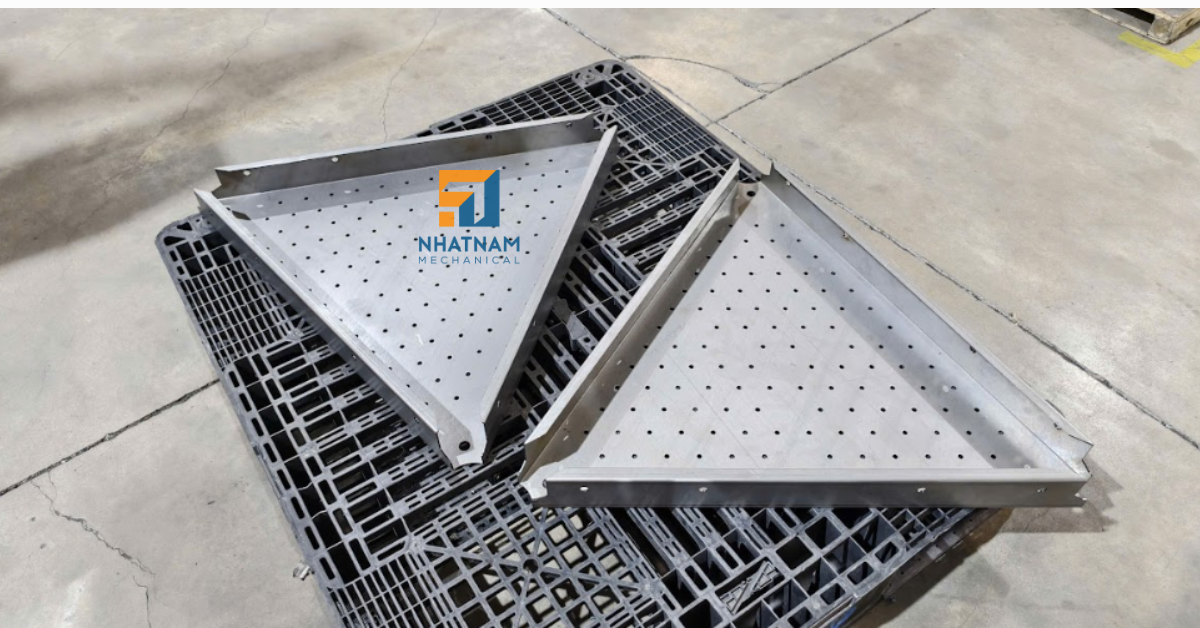

6. CNC Punching Capabilities at Nhat Nam Mechanical

At Nhat Nam Mechanical, we currently operate the TruPunch 1000 (S05) CNC punching machine — a high-performance system from TRUMPF, designed to meet the demands of precise and stable sheet metal processing in industrial production.

Thanks to this advanced technology platform, Nhat Nam Mechanical is capable of:

Performing complex hole and shape punching with high precision and stable repeatability

Meeting tight tolerance requirements for electrical cabinets, machine frames, and mechanical components

Maintaining high processing speeds suitable for both large-volume production and customized orders

Optimizing punching layouts to reduce material waste and effectively control production costs

The application of CNC punching technology not only increases productivity but also ensures consistent quality across production batches, creating a strong foundation for subsequent processes such as bending, welding, and assembly.

With a modern equipment system and a team of experienced technicians, Nhat Nam Mechanical is well prepared to meet precise sheet metal punching requirements and deliver efficient, sustainable manufacturing solutions for customers both domestically and internationally.