Sheet metal punching is a basic process in mechanical manufacturing, but it is an indispensable part of many industries. The process involves using a punching machine to create precise holes or shapes in metal sheets. The versatility and efficiency of sheet metal punching makes it a method used to produce a wide variety of components and products. Let’s take a closer look at how this technique is applied in different fields and why it is so important.

Sheet Metal Punching For The Automotive Industry

In the automotive industry, sheet metal punching plays an important role in the production of parts that require high precision. Punched components typically include brackets, panels, and structural parts. These punched parts are essential for vehicle assembly to tight tolerances and ensure safety and performance. For example, punched holes in sheet metal can be used to attach various components together, from engine components to interior accessories. The ability to consistently produce high-quality, precision parts is critical to vehicle reliability and safety.

In the Construction and Architecture Industry

Architects and builders use perforated metal panels for both decorative and functional purposes. For example, perforated metal panels can be used to create striking building facades that not only enhance visual appeal but also provide practical benefits such as improved airflow and natural light filtration. These metal panels are also used in roofing, ceilings, and interior partitions, adding a modern touch to a variety of building elements while maintaining durability.

Applications sheet metal punching in the Electronics Industry

The electronics industry relies heavily on sheet metal stamping technology to create enclosures, brackets, and connectors. Electronic devices often require metal parts to house delicate components and protect them from damage. High-precision stamping technology ensures that these metal enclosures are both secure, protective, and functional. For example, metal enclosures for computers, servers, and consumer electronics are often produced using sheet metal stamping technology, ensuring that they meet strict design and performance specifications.

Applications in Home Appliances

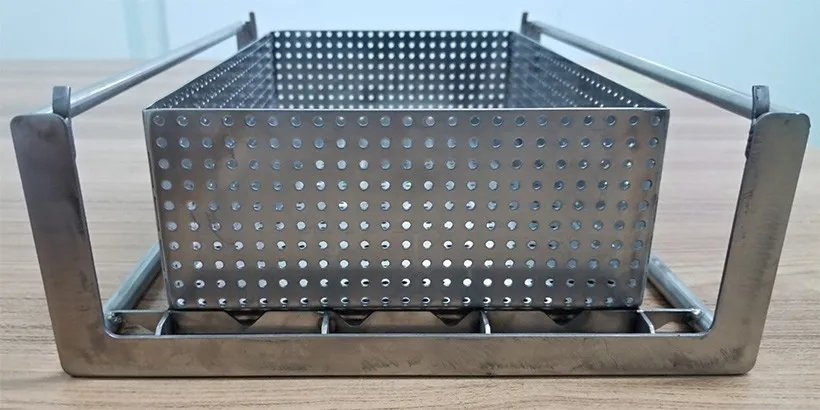

Home appliances, from washing machines to refrigerators, use sheet metal punching for many of their internal components. Parts such as frames, panels, and brackets are often punched from sheet metal to ensure they are strong and durable. This process allows manufacturers to produce these parts efficiently and with consistent quality, which is important for the long-term reliability and durability of home appliances. Punched parts often include precision holes for screws, ventilation, and other features necessary for the operation of the appliance.

Sheet Metal Punching in Industrial Equipment

In industry, sheet metal punching is used to create parts for machinery and equipment that are highly complex and require near-perfect precision. Components such as machine frames, housings, and functional parts are often produced using this technique. The ability to punch complex shapes and patterns from sheet metal means that manufacturers can produce equipment that is not only functional, but also meets specific operating requirements.

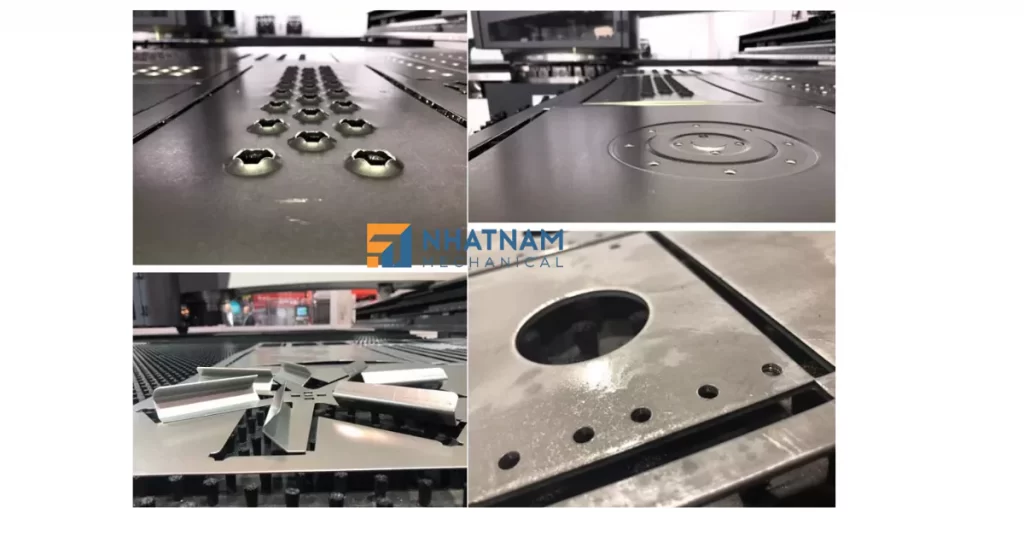

Prestigious sheet metal stamping company

Today, there are many mechanical processing companies, choosing a reputable and reliable processing place is not easy. You need to carefully research the processing workshop, machinery and equipment so that you can choose a processing place for your mechanical products.

Nhat Nam Mechanical Engineering with many years of experience in the mechanical processing profession, with techniques drawn from Japan and modern machinery and equipment, Nhat Nam can confidently create mechanical processing products with absolute precision, high aesthetics… Nhat Nam Mechanical Engineering will be a choice worth considering when choosing a mechanical processing company in Vietnam.

Contact Us

Ready to elevate your projects with high-quality custom steel components? Contact Nhat Nam Mechanical today to discuss your requirements and get a quote. Our dedicated team is here to provide you with exceptional service and solutions that meet your needs.

NHAT NAM MECHANICAL CO., LTD contact information: House No. 36, Garland – Phuoc Dien, 72 Duong Dinh Hoi, Phuoc Long B Ward, District 9, Ho Chi Minh City, Vietnam

Contact Japan

Email: tranquy@cokhinhatnam.vn

Tel: +84 938 771 508

Contact English

Email: marketing@cokhinhatnam.vn

Tel: +84 964 092 079

Contact Vietnam

Email: vinhnt@cokhinhatnam.vn

Tel: +84 964 084 479

By choosing Nhat Nam Mechanical, you are partnering with a trusted leader in custom steel components fabrication in Vietnam. Experience the difference in quality, precision, and service that sets us apart from the rest.