In modern industrial production, the sheet metal stamping process is a popular technique to create precise, uniform, and cost-effective parts. This process is widely used in the automotive, aerospace, electronics, medical, and home appliance industries. However, to achieve these benefits, the quality at...

Introduction In modern manufacturing, precision and consistency are key factors in creating high-quality products. Two popular technologies today are CNC tube bending and laser cutting, which are widely used in the automotive, aviation, furniture, and construction industries. However, no matter how modern the...

Sheet metal fabrication is the backbone of many industries — from construction and automotive to electronics and medical devices. While the concept may sound technical, the processes behind it are practical, versatile, and designed to transform raw sheet metal into precise, functional components....

In the mechanical engineering industry, especially in the field of sheet metal processing, choosing the right sheet metal processing factory is like finding the right “companion” for your project. A suitable partner will not only deliver the product as required and on time,...

In today’s competitive manufacturing landscape, precision sheet metal prototyping plays a crucial role in bridging the gap between design concepts and full-scale production. For both OEM manufacturers and companies with custom sheet metal fabrication needs, the ability to produce accurate, high-quality prototypes is...

1. Introduction In the sheet metal industry, bending is an extremely common process — used in making electrical cabinets, machine frames, boxes, and small components. However, if the bending rules are not properly followed, the product may crack, warp, end up with incorrect...

In the competitive world of sheet metal fabrication, surface finishing isn’t just about aesthetics—it’s about protection, durability, and performance. Among the various finishing options, powder coating stands out as a high-performance solution that enhances the longevity and appearance of metal parts. But what...

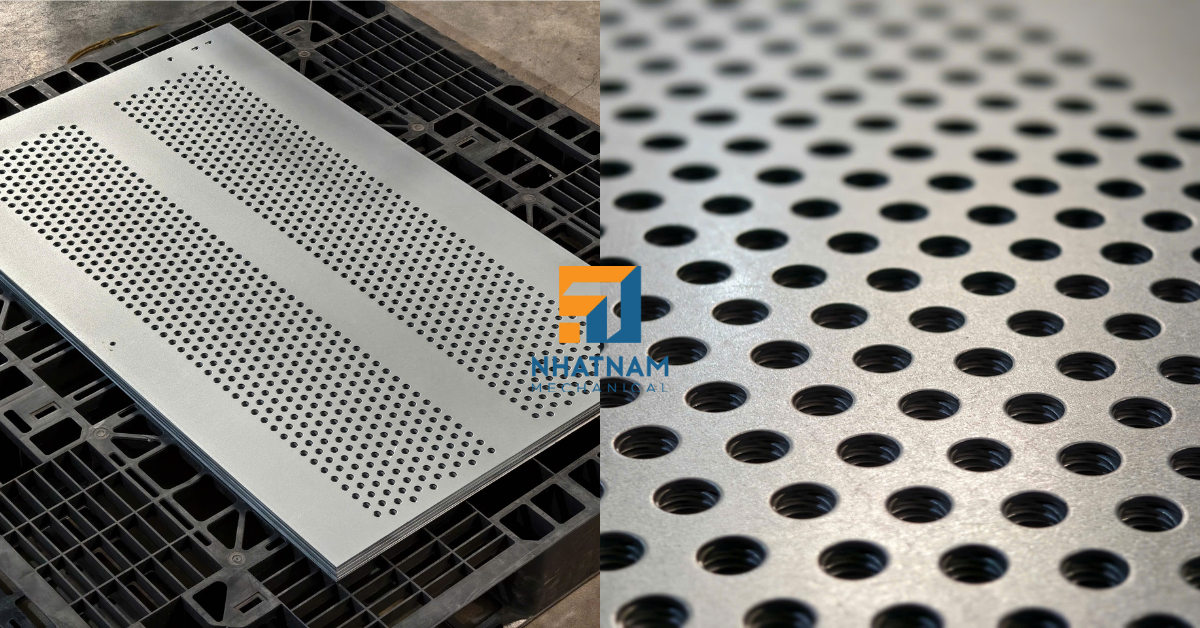

In today’s manufacturing world, what truly impresses engineers and designers isn’t just the size of machines or the scale of factories — it’s the precision. And few processes showcase this better than the sheet metal punching process. At first glance, punching may seem...

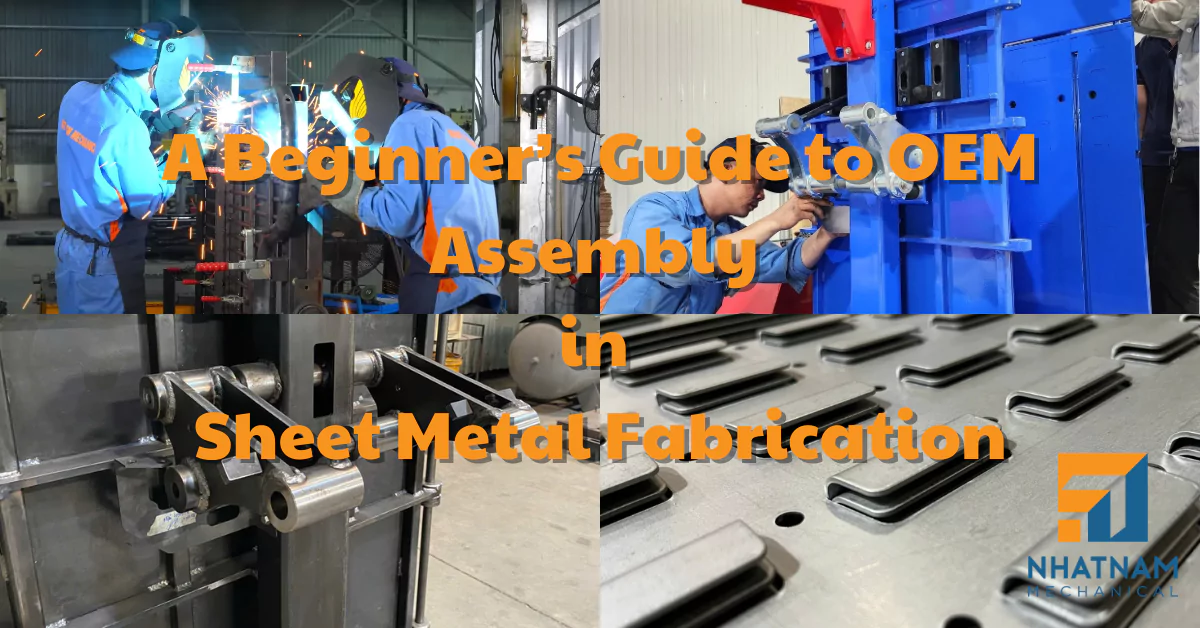

When it comes to custom manufacturing, OEM assembly plays a vital role in delivering high-quality, precision-engineered products—especially in the field of sheet metal fabrication. But what exactly is OEM assembly, and how does it benefit manufacturers and clients alike? This beginner-friendly guide breaks...

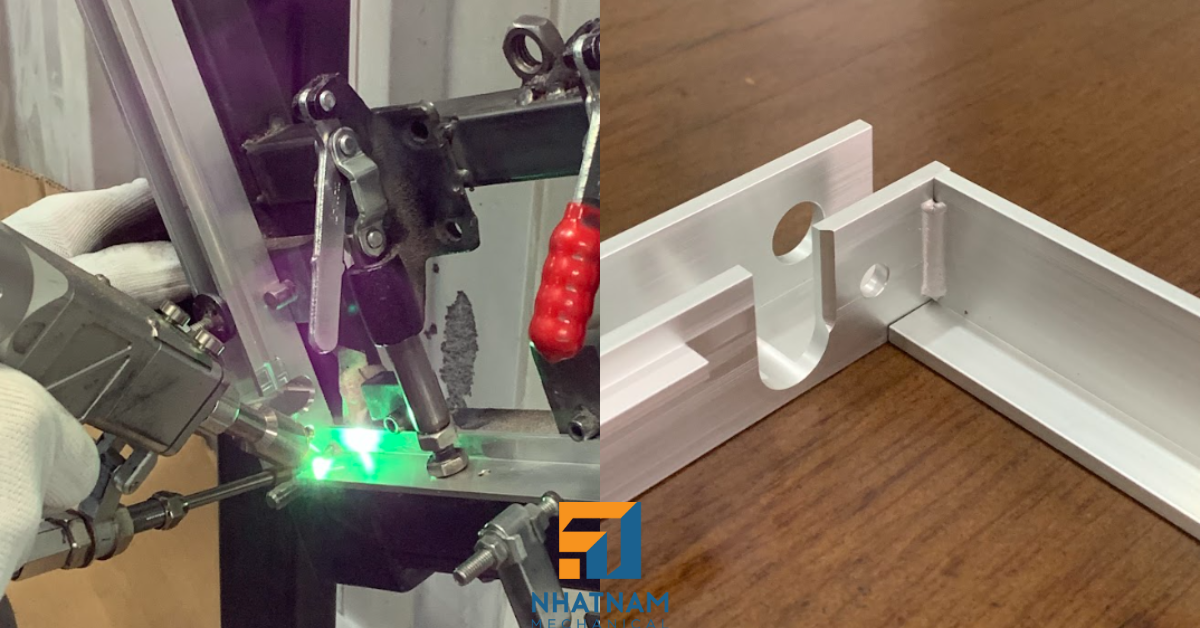

Ensuring the quality of welds in sheet metal processing not only helps maintain structural strength but also directly affects the life and safety of the product. This article presents methods of weld inspection through visual observation and the use of specialized equipment, analyzes...