Sheet metal laser cutting is one of the most advanced processing technologies today, allowing the creation of precise details, sharp cutting edges, and smooth surfaces without additional finishing. However, an important factor that directly affects cutting quality and productivity is the thickness of the material. Not all lasers can cut all thicknesses — and understanding this limitation helps businesses choose the right technology, avoid errors, and optimize costs.

1. Why Is the Thickness Limit Important in Laser Cutting?

Each laser cutting machine has different laser power and beam characteristics.

If the material is too thick compared to the machine’s capacity:

The cutting speed is significantly reduced, which may cause scorching or incomplete cuts.

The cutting edge becomes rough, with excess slag that affects product quality.

Energy is wasted, increasing production costs.

On the other hand, when choosing the right material thickness:

You achieve faster cutting speeds.

The surface is smoother with cleaner edges.

Auxiliary gas and electricity consumption are reduced.

2. Factors Affecting the Cutting Limit

There is no fixed value for the “maximum cutting thickness” in laser cutting, as this depends on many factors related to the machine, material, and operating conditions. Below are the main factors that influence cutting performance:

Laser Machine Technology and Configuration

Each laser cutting machine has a unique design — from the laser source, beam delivery system, focusing lens to the cooling mechanism.

Newer-generation machines with well-focused laser beams can concentrate energy more effectively, allowing thicker materials to be cut while maintaining high edge quality.

Type of Material

Different metals absorb laser energy differently:

Steel and stainless steel absorb laser energy well and are generally easy to cut.

Aluminum and copper reflect laser light and dissipate heat quickly, requiring more advanced cutting parameters and precision control.

Understanding the properties of each material helps technicians select the right cutting mode and assist gas, ensuring smooth and bright cut edges.

Types of Assist Gas

Oxygen (O₂): Commonly used for carbon steel, supports oxidation and helps cut thicker materials.

Nitrogen (N₂): Used for stainless steel or aluminum to produce bright, oxidation-free edges.

Air: A low-cost option suitable for thin sheets and non-critical parts.

Cutting Speed and Focus

Properly adjusting the cutting speed and focus position is critical to avoid burning or poor-quality edges, especially when processing thicker materials.

3. Signs That the Material Exceeds the Cutting Limit

During production, technicians can recognize when a material exceeds the machine’s cutting capability through the following signs:

The cutting edge appears dark or heavily discolored.

Slag or uneven grooves appear along the cutting path.

The end of the cut is not completely separated.

There are small sparks, popping sounds, or unstable light emission during cutting.

These signs indicate that the laser energy is insufficient to fully penetrate the material, or that the molten metal removal process is not well controlled.

4. How to Choose the Right Material Thickness When Designing a Product

When designing sheet metal components, engineers should:

Determine the material thickness that matches the available laser power.

Avoid using overly thick materials unless absolutely necessary.

Consider bend radius, hole size, and narrow slots, as laser cutting becomes less precise with thicker materials.

Refer to guidelines from the machine manufacturer or a professional fabrication partner such as Nhat Nam Mechanical to choose the most suitable thickness.

5. Nhat Nam Mechanical – Expert in Precision Sheet Metal Laser Cutting

At Nhat Nam Mechanical, we understand that every metal component has its own specific requirements.

With a high-tech laser cutting system and a team of experienced engineers, we can:

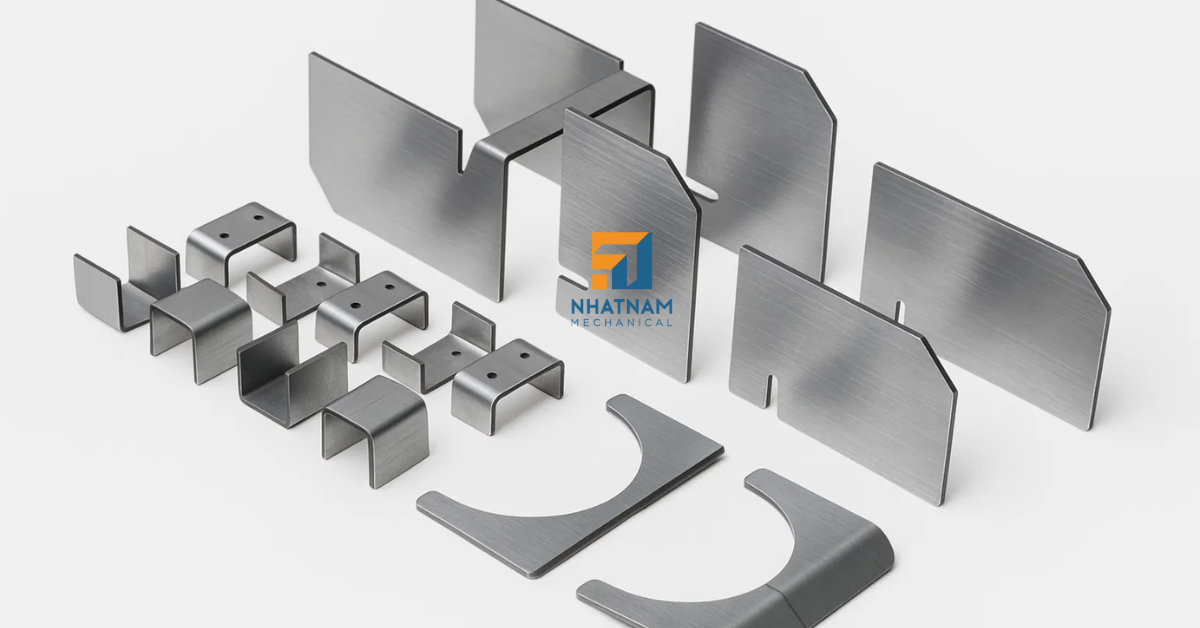

Precisely process a wide range of materials, including steel, stainless steel, and aluminum.

Advise customers on selecting the most suitable material thickness and cutting method.

Deliver clean, sharp, and smooth cuts without additional finishing.

Provide comprehensive services — from cutting, bending, welding to final assembly — meeting diverse production needs.

Understanding the material thickness limit in laser cutting helps businesses become more proactive in product design, reduce costs, and ensure consistent quality. Choosing the right technology and the right material is the key to achieving the highest efficiency in modern sheet metal fabrication.