Introduction

What is a Material Handling Equipment?

Material handling equipment plays an essential role in manufacturing, logistics and warehousing by improving the movement, storage and control of goods. These systems are designed to increase efficiency and reduce manual labor across various industries.

At Nhat Nam Mechanical, we understand that the durability and strength of a Material Handling Equipment depends heavily on the quality of the weld. That’s why we use advanced welding technologies and techniques to ensure that every joint, seam, and connection is strong, precise, and long-lasting.

Process

Precision Welding – The Backbone of Our OEM Material Handling Equipment

1. High-Quality Welding for Maximum Durability

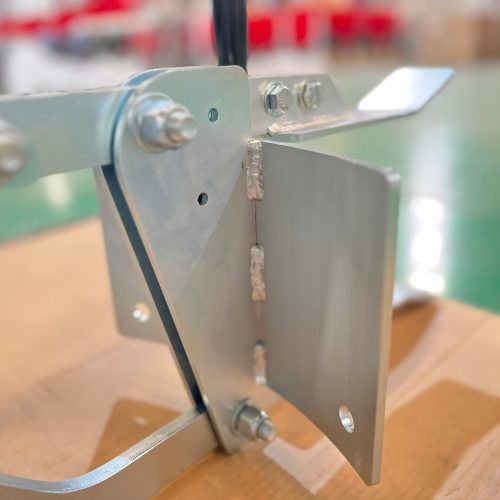

We specialize in TIG, MIG, laser and robotic welding, ensuring superior weld strength and seamless finishes. Additionally, all the joints are reinforced to prevent cracking, warping or damage from heavy use. Our precision welding technology ensures that each Material Handling Equipment can withstand heavy loads, frequent use and harsh environments without structural damage to the equipment.

2. Modern Robotic Welding for Consistency

By integrating robotic welding, we gain consistent welds, reducing defect rates and ensuring every product reachs the highest quality standards. The use of robotic welding also improves efficiency, accuracy and continuity, reducing errors in welding techniques.

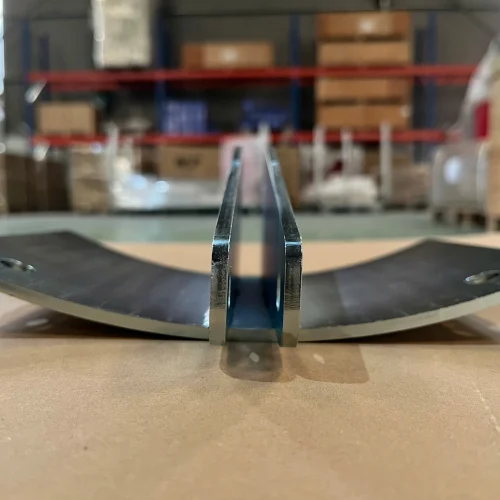

3. Rust-Free By Advanced Techniques

We understand that many kind of devices may be used in harsh environments such as offshore or high-humidity areas, where metal, especially weld joints, is prone to rust. Therefore, our welding process includes gas shielding, and the entire product undergoes plating treatment to ensure long-lasting durability.

4. Skilled Technicans & Strict Quality Control

Our team of experienced workers assembles and carefully checks every element of size, angle, color uniformity after plating, weld gap,... to ensure there are no errors. Each product after leaving the factory is precisely tested and guaranteed to have no issues during the operation of the product.

Benefits

Customized for Your Needs

OEM Material Handling Equipment services at Nhat Nam offers a wide range of customization options from personal size up to industrial size and material such as carbon steel or aluminum. You have full control to create a product that aligns perfectly fit your needs.

Commitment to Quality

The production process always strictly complies with ISO 9001:2015 standards with clear certification of raw material origin. Additionally, the application of state of the art equipments such as laser cutting, robotic welding ensures that every single item meets industry standards and exceeds your expectations.

Premium Advisory Service

Dedicated service and support provided by a team of qualified engineers who understand the complexities of Material Handling Equipment manufacturing, always ready to support any of your issues.

Flexibility in orders

Whether you need small batch production or mass order, we can adapt to your requirements, offering flexibility in any of your demands.

Why Chose Us?

Our dedicated experts work closely with you every step of the way to design, develop, and deliver the precision-crafted part and customized product.

With ISO 9001 Certification and ANSI Certification, only the top shops that apply to become network suppliers make it through our qualification process.

Our team of Application Engineers and Process Specialists are available to support you and provide answers to all of your fabrication and manufacturability questions.

Have an upcoming project?

Nhat Nam Factory

245 Phan Dang Luu, Tan Cang, Phuoc Tan, Bien Hoa, Dong Nai, Vietnam.

Email us

cokhinhatnam.info@gmail.com

Call us

(+84) 964 092 079 (EN) (+84) 964 084 479 (VN) (+84) 938 77 15 08 (JPN)