Sheet metal manufacturing is an essential part of modern industry, to better understand the complexities involved in this process and its significant impact on our daily lives, please refer to the following article to better understand.

Understanding the Basics of Sheet Metal Manufacturing

At its core, sheet metal manufacturing involves taking thin, flat pieces of metal—often steel, aluminum, or copper—and transforming them into specific shapes and structures. This transformation is achieved through a series of processes, including cutting, bending, and assembling. While this might seem straightforward, the reality is far more intricate, requiring both advanced technology and highly skilled labor.

- Cutting: The first step in sheet metal manufacturing typically involves cutting the metal sheets into desired shapes and sizes. Various techniques are used, ranging from traditional methods like shearing and sawing to more advanced methods such as laser cutting, plasma cutting, or waterjet cutting. Each method offers different levels of precision and is chosen based on the specific requirements of the project.

- Bending: After the metal is cut, the next step is to bend it into the desired shape. Bending can be performed using a variety of tools, including press brakes, roll benders, or manual bending techniques. The goal is to achieve the precise angles and curves needed for the final product, whether it’s a simple bracket or a complex structural component.

- Assembling: The final step in the process is assembling the various pieces into a finished product. This can involve welding, riveting, or using adhesives, depending on the materials and the intended use of the final product. The assembly process is crucial, as it ensures that the individual components come together seamlessly to create a durable and functional end product.

The Importance of Sheet Metal Manufacturing in Modern Industry

Sheet metal manufacturing isn’t just a technical process—it’s a critical component of countless industries that drives innovation and efficiency. Consider the automotive industry, for example. Every car on the road today has components made through sheet metal manufacturing. The body panels, chassis, and even some internal parts are all crafted using these techniques. Without them, we wouldn’t have the safe, reliable vehicles we depend on.

The construction industry also relies heavily on sheet metal manufacturing, from the steel beams that form the skeletons of skyscrapers to the HVAC systems that regulate indoor climates, sheet metal is everywhere. The precision and versatility of sheet metal manufacturing make it possible to create custom solutions for complex architectural designs, ensuring that buildings are not only functional but also aesthetically pleasing.

In the electronics industry, sheet metal is used to create enclosures, brackets, and other components that protect sensitive electronic parts. The ability to produce these components quickly and accurately is crucial for companies that need to stay ahead in a fast-paced, competitive market.

Why Quality Matters in Sheet Metal Manufacturing

The quality of sheet metal manufacturing directly impacts the performance, durability, and safety of the final product. Poorly manufactured components can lead to failures, costly repairs, and even dangerous situations. This is why choosing the right sheet metal manufacturer is so important. A reputable manufacturer will use state-of-the-art equipment, adhere to strict quality control standards, and employ skilled workers who understand the intricacies of the process.

Moreover, advancements in technology have made it possible to achieve even greater precision and efficiency in sheet metal manufacturing. Automation, for example, allows for faster production times and reduces the likelihood of human error. This not only improves the quality of the final product but also helps reduce costs, making sheet metal manufacturing more accessible to a wider range of industries.

The Future of Sheet Metal Manufacturing

As industries continue to evolve, so too does the field of sheet metal manufacturing. Emerging technologies, such as additive manufacturing (3D printing) and advanced robotics, are beginning to complement traditional techniques, offering new possibilities for customization and innovation. These advancements are likely to shape the future of sheet metal manufacturing, making it an even more integral part of modern industry.

In conclusion, sheet metal manufacturing is a vital process that underpins much of the technology and infrastructure we rely on today. From its basic processes to its wide-ranging applications, it’s clear that this field will continue to play a key role in the advancement of industries worldwide.

Nhat Nam Mechanical: Leading the Future of Sheet Metal Manufacturing

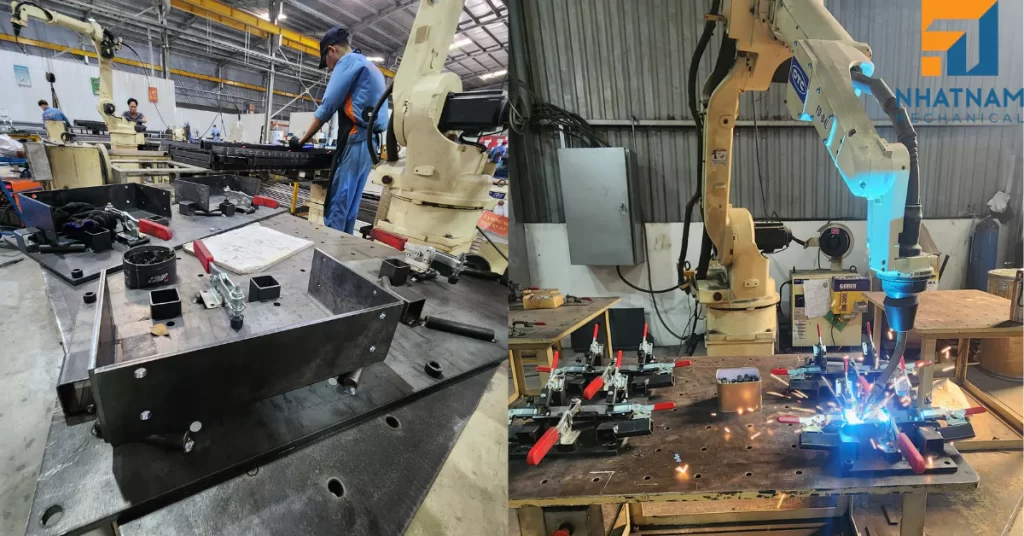

As industries evolve, so do the techniques and technologies in sheet metal manufacturing. At Nhat Nam Mechanical, we stay ahead of the curve by embracing the latest advancements in automation and robotics. This allows us to produce complex, custom-designed components efficiently and cost-effectively, helping our clients stay competitive in their markets.

Our commitment to innovation and quality makes Nhat Nam Mechanical the ideal partner for any business in need of top-tier sheet metal manufacturing services. Whether you need large-scale production or specialized, custom components, we have the expertise and equipment to deliver.

In conclusion, sheet metal manufacturing is more than just a process—it’s a critical part of modern industry, and at Nhat Nam Mechanical, we’re proud to be leading the way. Contact us today to learn how our sheet metal manufacturing services can support your business’s success.

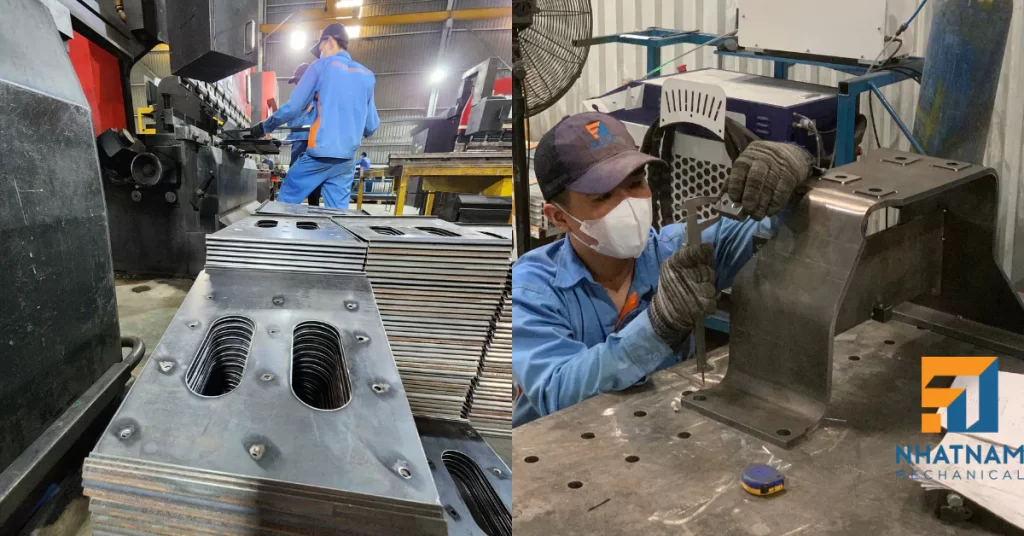

At Nhat Nam Mechanical, we specialize in transforming flat pieces of metal into functional, high-quality components. Sheet metal manufacturing starts with cutting, where advanced techniques such as laser cutting and plasma cutting are used to achieve precise shapes and sizes. This step is crucial, and our state-of-the-art equipment ensures that each cut meets the highest standards.

Next comes bending, where the metal is shaped into the required forms. Whether it’s simple bends or complex curves, our skilled team uses press brakes and roll benders to create components that fit perfectly into their intended applications.

Finally, the assembly process brings everything together. At Nhat Nam Mechanical, we utilize welding, riveting, and other methods to ensure that every product we manufacture is durable and reliable, meeting both industry standards and our clients’ specific needs.

Why Choose Nhat Nam Mechanical for Sheet Metal Manufacturing?

The importance of quality in sheet metal manufacturing cannot be overstated. Poorly made components can lead to failures, inefficiencies, and even safety hazards. That’s why Nhat Nam Mechanical is committed to delivering excellence in every project we undertake.

Our clients across various industries, including automotive, construction, and electronics, trust us to provide sheet metal components that are not only precisely made but also designed to last. With years of experience and a dedication to innovation, Nhat Nam Mechanical ensures that every product we deliver meets the highest standards of quality and performance.

Contact Us

Ready to elevate your projects with high-quality custom steel components? Contact Nhat Nam Mechanical today to discuss your requirements and get a quote. Our dedicated team is here to provide you with exceptional service and solutions that meet your needs.

NHAT NAM MECHANICAL CO., LTD contact information: House No. 36, Garland – Phuoc Dien, 72 Duong Dinh Hoi, Phuoc Long B Ward, District 9, Ho Chi Minh City, Vietnam

Contact Japan

Email: tranquy@cokhinhatnam.vn

Tel: +84 938 771 508

Contact English

Email: marketing@cokhinhatnam.vn

Tel: +84 964 092 079

Contact Vietnam

Email: vinhnt@cokhinhatnam.vn

Tel: +84 964 084 479

By choosing Nhat Nam Mechanical, you are partnering with a trusted leader in custom steel components fabrication in Vietnam. Experience the difference in quality, precision, and service that sets us apart from the rest.